Civil Engineering Team

A leader in the design and implementation of the latest and the most innovative engineering methods

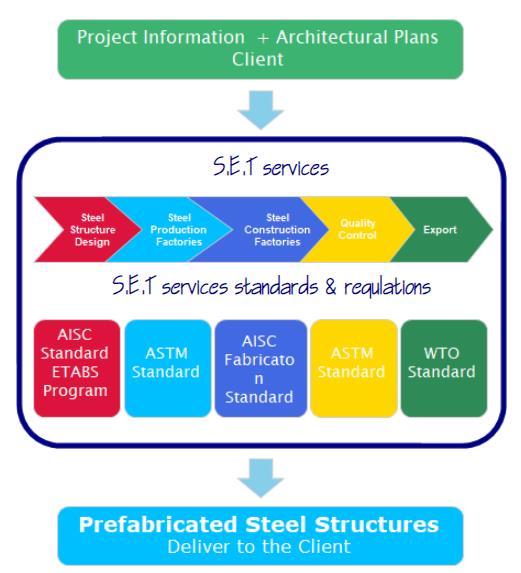

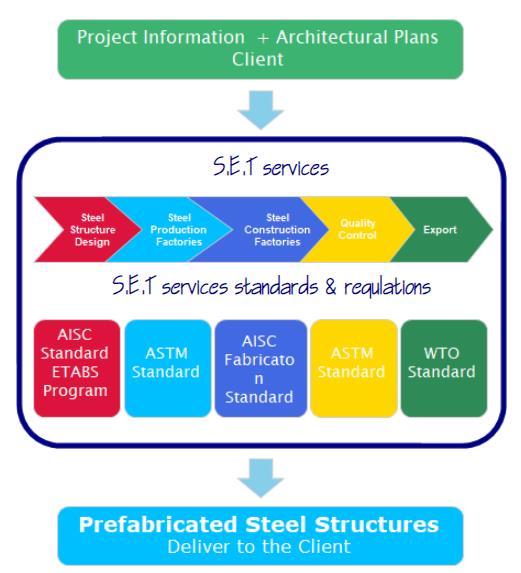

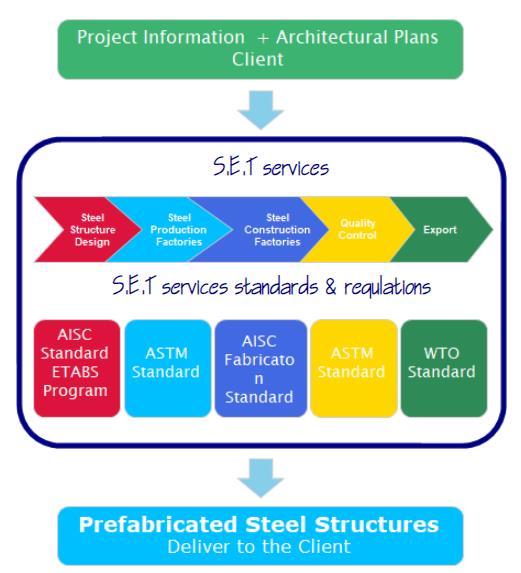

Export Procedure

According to information and architectural drawings of the clients desire, we design the structure, carry out all the stages of construction, and send the constructed prefabricated steel structure for installation to the client.

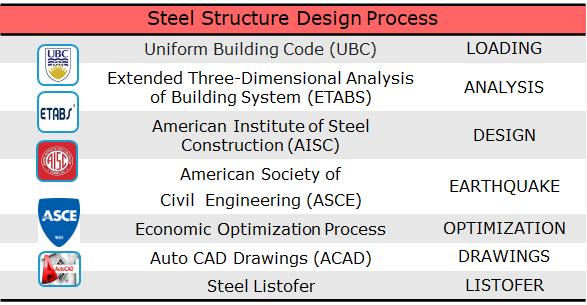

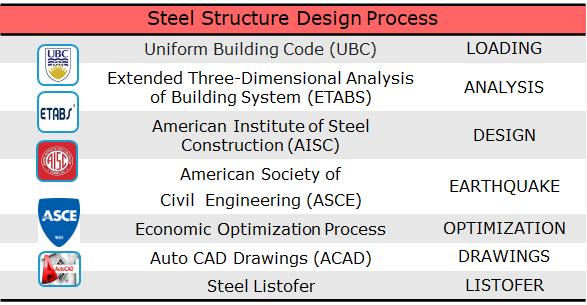

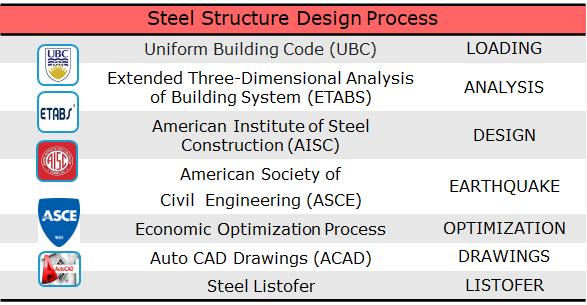

Steel Structure Design and Analysis

The prefabricated steel structures are designed according to the information and architectural drawings desired by esteemed clients. The SETs experienced and expert engineers use this information to design and analyze prefab steel structures based on the highest international standards and regulations. The PSS is designed with maximum efficiency and subtility to provide an optimum structure in economic and engineering aspects.

Steel Production

Iran maintained its position as the 10th largest global steel producer. Iran's production of steel constitutes 70% of total steel production in the Middle East.

- Variety of steel products - Iran is one of the few countries that has a comprehensive steel production industry locally, and everything from iron to products such as rebar and frame sections are produced there. The variety of steel products in Iran is very high, for example, more than 40 factories are currently active in the field of rebar production alone.

- High quality - Steel products are produced with very high qualities that satisfy famous and valid international standards certified in a large number of countries.

- Reasonable price The cost of steel products in Iran is much lower than in many other countries. This is due to many factors such as the existence of abundant mines, indigenous high-tech knowledge and technology, abundant and cheap energy sources, cheap labor, and the low relative value of the national currency compared to others.

- Low transportation costs The common sea and land border between Iran and its neighbors reduces the cost of transportation compared to transporting costs from many other countries outside of the area.

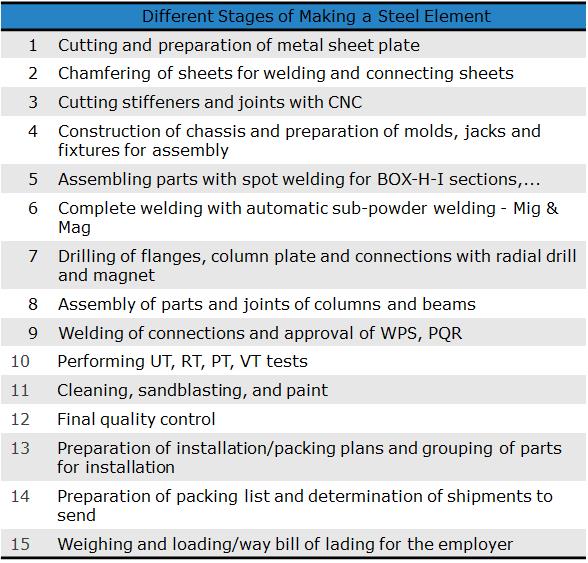

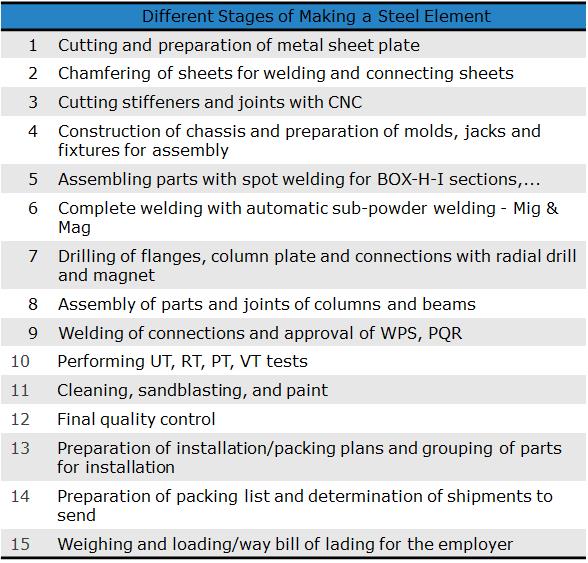

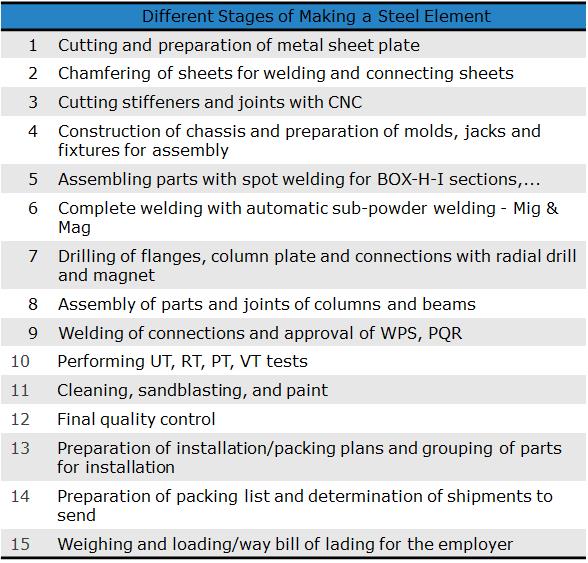

Construction

At this stage, detailed construction plans are prepared based on structure design to start the machinery process. The main elements of the structure, including beams and columns, and secondary parts, such as stairs and connections, are constructed. At each stage, construction control tests and inspections are carried out to maintain the desired standard. After the construction, sandblasting is carried out for each part, and installation details are prepared and attached for each group of elements. Finally, the prefab steel structure package is sent to the client along with the installation drawings.

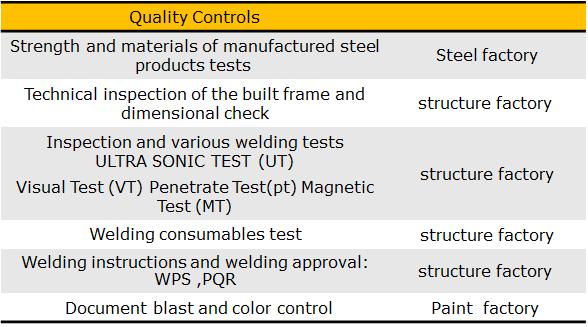

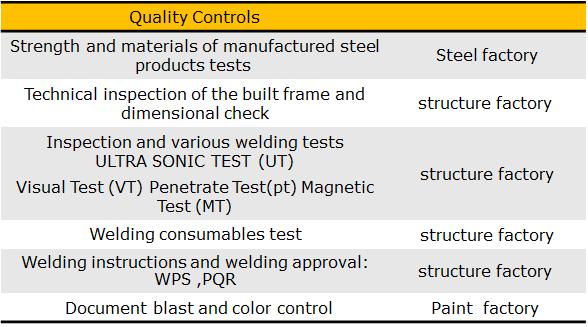

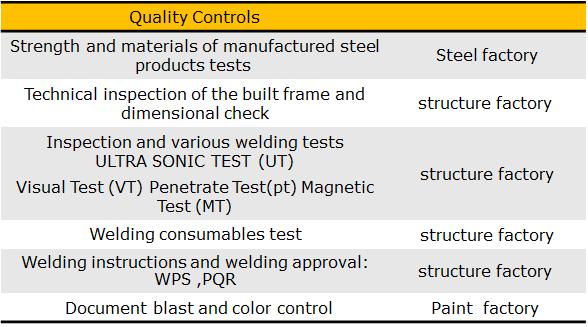

Quality Controls

At each stage, various control tests are executed in order to ensure the high quality of the materials, correct implementation of the construction methods, and the approved constructed part. At first, the strength and material tests are executed at the factory site to ensure the high quality of the steel. Afterward, various inspections and tests such as welding and resistance testing of elements are performed to ensure the quality of construction in the manufacturing process. Consequently, the results of the tests are provided for the client along with each shipment.

Export Licenses and Permissions From Iran

Service description: Various requirements, legal formalities, and fees are carried out to obtain export permissions and licenses in the origin country. The full transportation responsibility of the prefab steel structure in the origin country lies with the SET company. In the destination country, clearance procedures and customs fees are the responsibility of the client. Once the goods arrive at the agreed-upon location, the buyer becomes responsible for paying import duties, as well as further transport costs: Delivered Duty Unpaid (DDU).

Export Procedure

According to information and architectural drawings of the clients desire, we design the structure, carry out all the stages of construction, and send the constructed prefabricated steel structure for installation to the client.

Export Procedure

According to information and architectural drawings of the clients desire, we design the structure, carry out all the stages of construction, and send the constructed prefabricated steel structure for installation to the client.

Steel Structure Design and Analysis

The prefabricated steel structures are designed according to the information and architectural drawings desired by esteemed clients. The SETs experienced and expert engineers use this information to design and analyze prefab steel structures based on the highest international standards and regulations. The PSS is designed with maximum efficiency and subtility to provide an optimum structure in economic and engineering aspects.

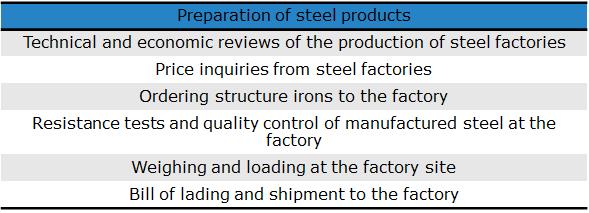

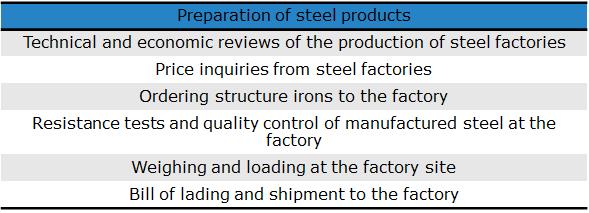

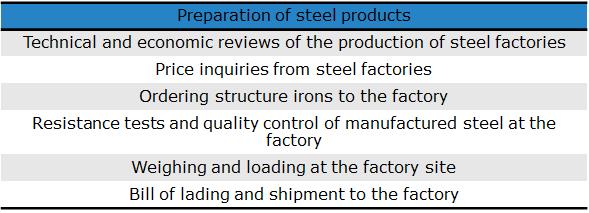

Steel Production

Iran maintained its position as the 10th largest global steel producer. Iran's production of steel constitutes 70% of total steel production in the Middle East.

- Variety of steel products - Iran is one of the few countries that has a comprehensive steel production industry locally, and everything from iron to products such as rebar and frame sections are produced there. The variety of steel products in Iran is very high, for example, more than 40 factories are currently active in the field of rebar production alone.

- High quality - Steel products are produced with very high qualities that satisfy famous and valid international standards certified in a large number of countries.

- Reasonable price The cost of steel products in Iran is much lower than in many other countries. This is due to many factors such as the existence of abundant mines, indigenous high-tech knowledge and technology, abundant and cheap energy sources, cheap labor, and the low relative value of the national currency compared to others.

- Low transportation costs The common sea and land border between Iran and its neighbors reduces the cost of transportation compared to transporting costs from many other countries outside of the area.

Construction

At this stage, detailed construction plans are prepared based on structure design to start the machinery process. The main elements of the structure, including beams and columns, and secondary parts, such as stairs and connections, are constructed. At each stage, construction control tests and inspections are carried out to maintain the desired standard. After the construction, sandblasting is carried out for each part, and installation details are prepared and attached for each group of elements. Finally, the prefab steel structure package is sent to the client along with the installation drawings.

Quality Controls

At each stage, various control tests are executed in order to ensure the high quality of the materials, correct implementation of the construction methods, and the approved constructed part. At first, the strength and material tests are executed at the factory site to ensure the high quality of the steel. Afterward, various inspections and tests such as welding and resistance testing of elements are performed to ensure the quality of construction in the manufacturing process. Consequently, the results of the tests are provided for the client along with each shipment.

Export Licenses and Permissions From Iran

Service description: Various requirements, legal formalities, and fees are carried out to obtain export permissions and licenses in the origin country. The full transportation responsibility of the prefab steel structure in the origin country lies with the SET company. In the destination country, clearance procedures and customs fees are the responsibility of the client. Once the goods arrive at the agreed-upon location, the buyer becomes responsible for paying import duties, as well as further transport costs: Delivered Duty Unpaid (DDU).

Steel Structure Design and Analysis

The prefabricated steel structures are designed according to the information and architectural drawings desired by esteemed clients. The SETs experienced and expert engineers use this information to design and analyze prefab steel structures based on the highest international standards and regulations. The PSS is designed with maximum efficiency and subtility to provide an optimum structure in economic and engineering aspects.

Steel Production

Iran maintained its position as the 10th largest global steel producer. Iran's production of steel constitutes 70% of total steel production in the Middle East.

- Variety of steel products - Iran is one of the few countries that has a comprehensive steel production industry locally, and everything from iron to products such as rebar and frame sections are produced there. The variety of steel products in Iran is very high, for example, more than 40 factories are currently active in the field of rebar production alone.

- High quality - Steel products are produced with very high qualities that satisfy famous and valid international standards certified in a large number of countries.

- Reasonable price The cost of steel products in Iran is much lower than in many other countries. This is due to many factors such as the existence of abundant mines, indigenous high-tech knowledge and technology, abundant and cheap energy sources, cheap labor, and the low relative value of the national currency compared to others.

- Low transportation costs The common sea and land border between Iran and its neighbors reduces the cost of transportation compared to transporting costs from many other countries outside of the area.

Construction

At this stage, detailed construction plans are prepared based on structure design to start the machinery process. The main elements of the structure, including beams and columns, and secondary parts, such as stairs and connections, are constructed. At each stage, construction control tests and inspections are carried out to maintain the desired standard. After the construction, sandblasting is carried out for each part, and installation details are prepared and attached for each group of elements. Finally, the prefab steel structure package is sent to the client along with the installation drawings.

Quality Controls

At each stage, various control tests are executed in order to ensure the high quality of the materials, correct implementation of the construction methods, and the approved constructed part. At first, the strength and material tests are executed at the factory site to ensure the high quality of the steel. Afterward, various inspections and tests such as welding and resistance testing of elements are performed to ensure the quality of construction in the manufacturing process. Consequently, the results of the tests are provided for the client along with each shipment.

Export Licenses and Permissions From Iran

Service description: Various requirements, legal formalities, and fees are carried out to obtain export permissions and licenses in the origin country. The full transportation responsibility of the prefab steel structure in the origin country lies with the SET company. In the destination country, clearance procedures and customs fees are the responsibility of the client. Once the goods arrive at the agreed-upon location, the buyer becomes responsible for paying import duties, as well as further transport costs: Delivered Duty Unpaid (DDU).