Civil Engineering Team

A leader in the design and implementation of the latest and the most innovative engineering methods

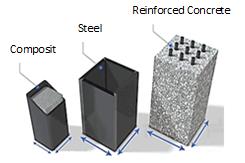

Advantages of Prefabricated Steel Structures

Prefabricated steel structures are a suitable alternative to conventional structures due to their technical and operational advantages. Interestingly, the PSS is more economical compared to conventional structures due to the optimized design carried out by our experienced engineers. Some benefits of PSS compared are as follows:

Due to the advantages of prefabricated steel structures, various countries such as China, Australia, and North America plan to increase the use of this type of structures by 20%.

Advantages of bolted joints

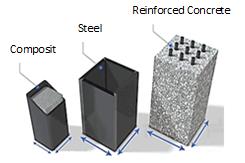

Advantages of Prefabricated Steel Structures

Prefabricated steel structures are a suitable alternative to conventional structures due to their technical and operational advantages. Interestingly, the PSS is more economical compared to conventional structures due to the optimized design carried out by our experienced engineers. Some benefits of PSS compared are as follows:

Due to the advantages of prefabricated steel structures, various countries such as China, Australia, and North America plan to increase the use of this type of structures by 20%.

Advantages of bolted joints

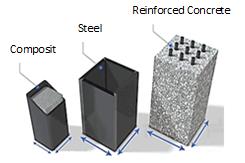

Advantages of Prefabricated Steel Structures

Prefabricated steel structures are a suitable alternative to conventional structures due to their technical and operational advantages. Interestingly, the PSS is more economical compared to conventional structures due to the optimized design carried out by our experienced engineers. Some benefits of PSS compared are as follows:

Due to the advantages of prefabricated steel structures, various countries such as China, Australia, and North America plan to increase the use of this type of structures by 20%.

Advantages of bolted joints