Civil Engineering Team

A leader in the design and implementation of the latest and the most innovative engineering methods

Seismic Isolation

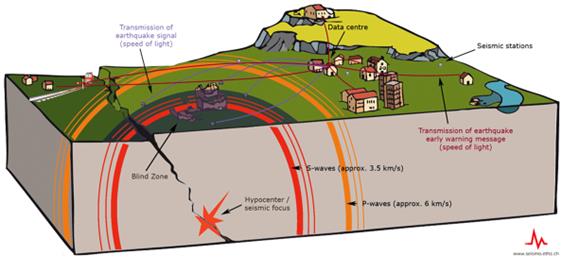

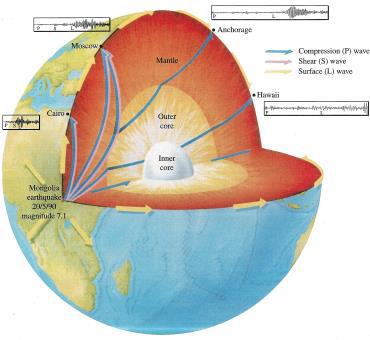

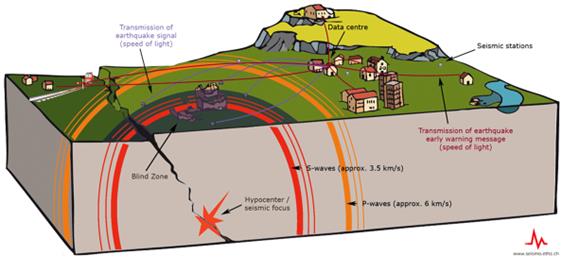

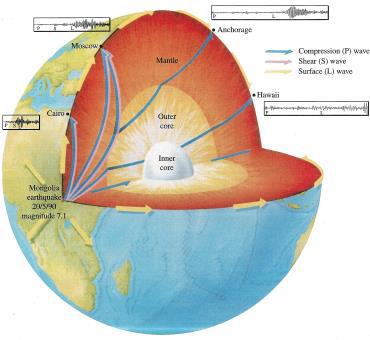

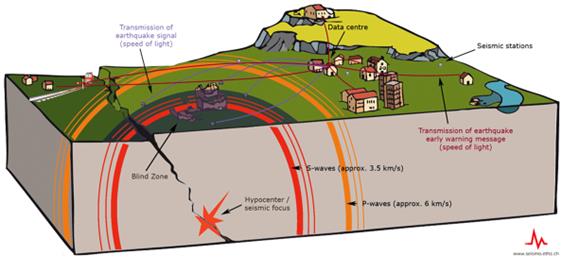

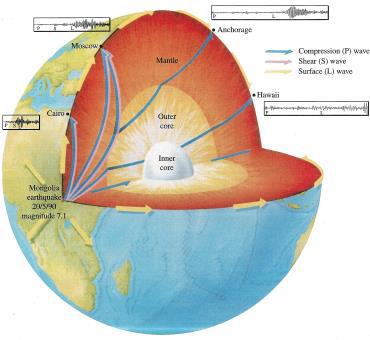

From the beginning of the world, earthquakes have occurred and will continue happening in the future. The most dramatic and memorable images of earthquake damages are indeed those of structural collapse. There are two fundamental approaches to mitigate earthquake damages on structures. The first approach is fortifying the structural lateral resistance system in order to tolerate exerted earth motion forces. These systems include moment resistance frames, shear walls and braces. Diminishing earthquake forces before entering into the structure states as the second approach.

The first approach which is known by name of conventional method is well-known, constructor-accepted and it has been widely used within the engineering practice. However, this method increases dead load of structure which can be undesirably costly. The second approach is less practiced in the literature and needs to be more explored.

The main goal of partake quake-attenuating in buildings is to absorb energy and to attenuate the exerted forces into structures as a result of ground motions. Quake-attenuating systems are divided into two main categories of Dampers and Isolators. Quake-attenuating systems restrain transmission of forces into the structure; therefore, they make considerable subsidence in story acceleration and story drifts that overall result is visible in designing forces carried by each elements.

Notwithstanding achievements and developments in the field of quake-attenuating systems, applying them in the structures is proportional to following complicated technology and subtle engineering. Furthermore, installation and initiation of this systems depend on educated and expert crews and such attenuating systems need maintenance and repair during the useful structural life time. The aforementioned reasons lead to limitation and high-cost of utilizing such system especially in developing countries. Consequently, nowadays civil engineering suffers from the lack of such quake-attenuating systems to be able to respond simply but applicable mechanism at the same time for almost all types of structure.

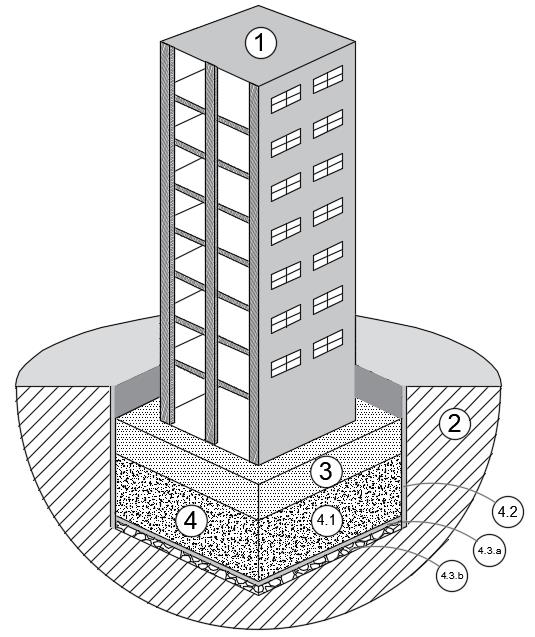

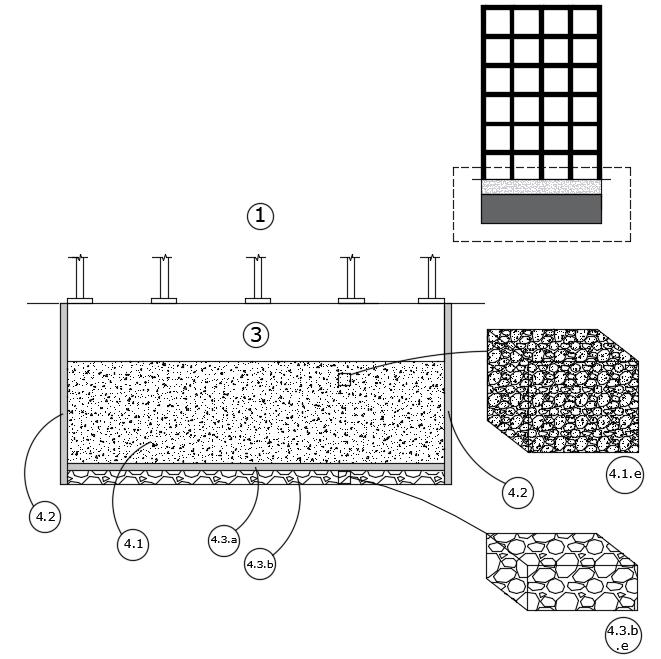

Earthquake Resistance System

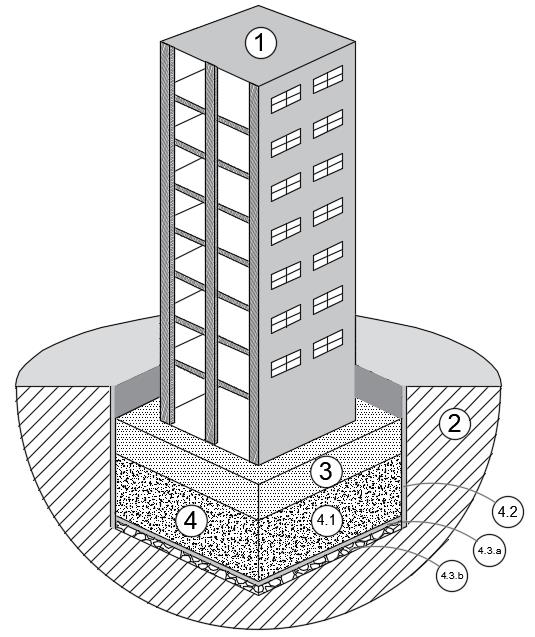

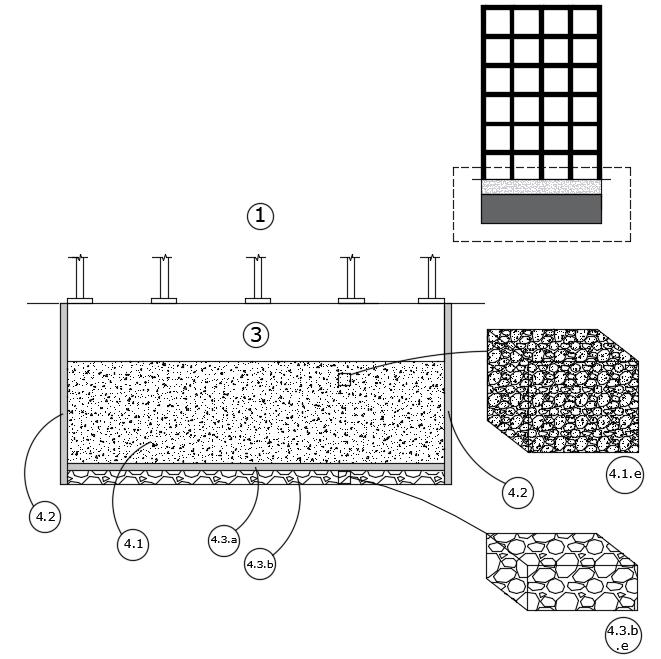

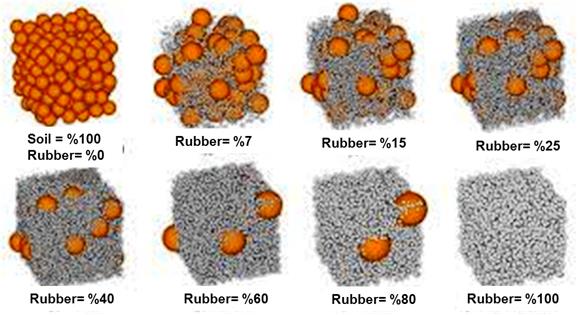

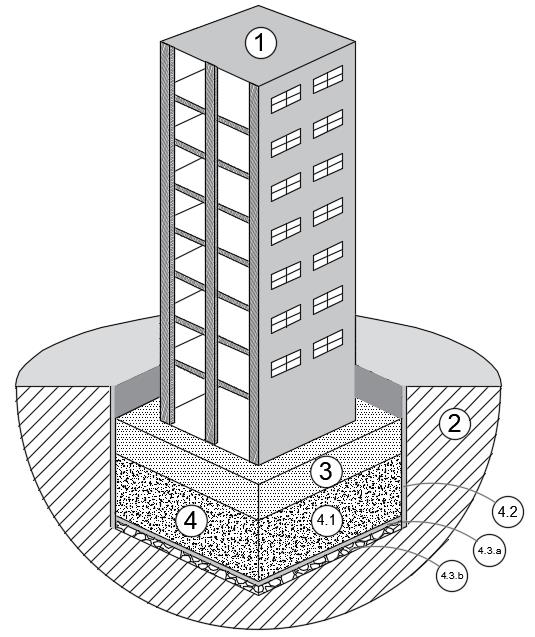

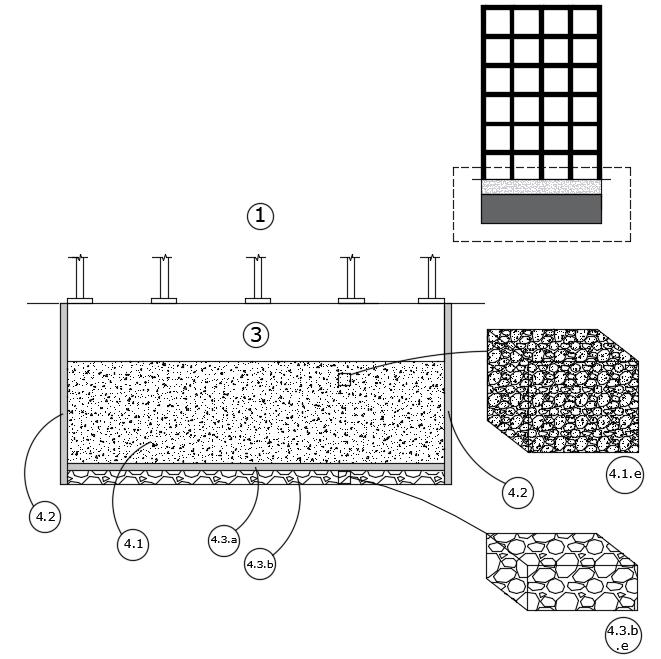

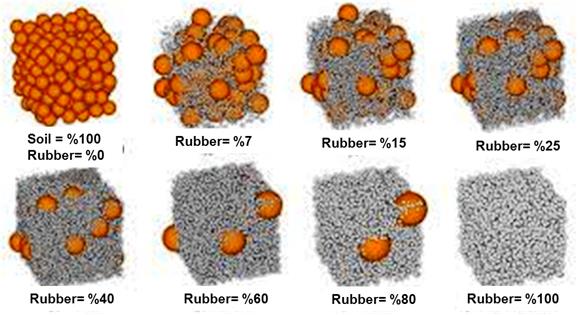

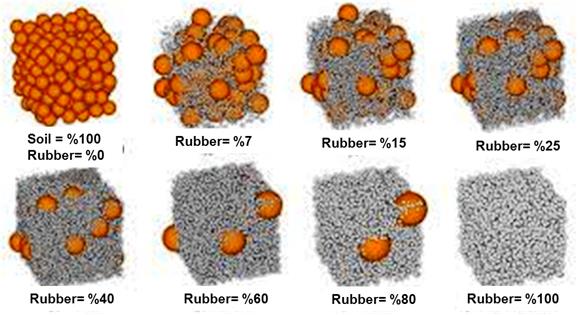

Nowadays civil engineering suffers from the lack of such quake-attenuating systems to be able to respond simply but applicable mechanism at the same time for almost all types of structure. Inspired by Patent No.: US 6,862,848B1, year 2008 Tsang published an article and introduced new system of isolation (Tsang 2008). This system is formed from rubber and soil mixture located in the base ground under structure foundation. Tsang showed the ability of mitigation of earthquake energy and isolation wave transition of this system for a ten story building. Afterward Kaneko conducted pseudo-dynamic response test and concluded that this system is effective for both seismic isolation and to prevent liquefaction and Xiong proposed that seismic isolation per-formance of rubber soil mixture is inferior to that of a foundation underlain by pure-sand, carried out by shak-ing table tests with a 1/3 scale rubbersoil mixtures model. All these evaluations prove the isolation ability of rubber-soil mixture as an isolator system. Therefore, researches over this new idea has begun and researches such as Senetakis et al. has started to find the behavioral parameters of rubber-soil mixture

Geo-Isolator Advantages

Geo-isolator is a new isolation system, which is located in the ground under the foundation. This system mit-igates earthquake peak acceleration such that for the worst case of ground 0.7g excitation, isolated structure experiences 0.35g peak acceleration. Results of this research are offered in the form of design spectra, by evaluating seven scaled excitations soil response analyses. The important outcomes of this research are as follow:

Seismic Isolation

From the beginning of the world, earthquakes have occurred and will continue happening in the future. The most dramatic and memorable images of earthquake damages are indeed those of structural collapse. There are two fundamental approaches to mitigate earthquake damages on structures. The first approach is fortifying the structural lateral resistance system in order to tolerate exerted earth motion forces. These systems include moment resistance frames, shear walls and braces. Diminishing earthquake forces before entering into the structure states as the second approach.

The first approach which is known by name of conventional method is well-known, constructor-accepted and it has been widely used within the engineering practice. However, this method increases dead load of structure which can be undesirably costly. The second approach is less practiced in the literature and needs to be more explored.

The main goal of partake quake-attenuating in buildings is to absorb energy and to attenuate the exerted forces into structures as a result of ground motions. Quake-attenuating systems are divided into two main categories of Dampers and Isolators. Quake-attenuating systems restrain transmission of forces into the structure; therefore, they make considerable subsidence in story acceleration and story drifts that overall result is visible in designing forces carried by each elements.

Notwithstanding achievements and developments in the field of quake-attenuating systems, applying them in the structures is proportional to following complicated technology and subtle engineering. Furthermore, installation and initiation of this systems depend on educated and expert crews and such attenuating systems need maintenance and repair during the useful structural life time. The aforementioned reasons lead to limitation and high-cost of utilizing such system especially in developing countries. Consequently, nowadays civil engineering suffers from the lack of such quake-attenuating systems to be able to respond simply but applicable mechanism at the same time for almost all types of structure.

Earthquake Resistance System

Nowadays civil engineering suffers from the lack of such quake-attenuating systems to be able to respond simply but applicable mechanism at the same time for almost all types of structure. Inspired by Patent No.: US 6,862,848B1, year 2008 Tsang published an article and introduced new system of isolation (Tsang 2008). This system is formed from rubber and soil mixture located in the base ground under structure foundation. Tsang showed the ability of mitigation of earthquake energy and isolation wave transition of this system for a ten story building. Afterward Kaneko conducted pseudo-dynamic response test and concluded that this system is effective for both seismic isolation and to prevent liquefaction and Xiong proposed that seismic isolation per-formance of rubber soil mixture is inferior to that of a foundation underlain by pure-sand, carried out by shak-ing table tests with a 1/3 scale rubbersoil mixtures model. All these evaluations prove the isolation ability of rubber-soil mixture as an isolator system. Therefore, researches over this new idea has begun and researches such as Senetakis et al. has started to find the behavioral parameters of rubber-soil mixture

Geo-Isolator Advantages

Geo-isolator is a new isolation system, which is located in the ground under the foundation. This system mit-igates earthquake peak acceleration such that for the worst case of ground 0.7g excitation, isolated structure experiences 0.35g peak acceleration. Results of this research are offered in the form of design spectra, by evaluating seven scaled excitations soil response analyses. The important outcomes of this research are as follow:

Seismic Isolation

From the beginning of the world, earthquakes have occurred and will continue happening in the future. The most dramatic and memorable images of earthquake damages are indeed those of structural collapse. There are two fundamental approaches to mitigate earthquake damages on structures. The first approach is fortifying the structural lateral resistance system in order to tolerate exerted earth motion forces. These systems include moment resistance frames, shear walls and braces. Diminishing earthquake forces before entering into the structure states as the second approach.

The first approach which is known by name of conventional method is well-known, constructor-accepted and it has been widely used within the engineering practice. However, this method increases dead load of structure which can be undesirably costly. The second approach is less practiced in the literature and needs to be more explored.

The main goal of partake quake-attenuating in buildings is to absorb energy and to attenuate the exerted forces into structures as a result of ground motions. Quake-attenuating systems are divided into two main categories of Dampers and Isolators. Quake-attenuating systems restrain transmission of forces into the structure; therefore, they make considerable subsidence in story acceleration and story drifts that overall result is visible in designing forces carried by each elements.

Notwithstanding achievements and developments in the field of quake-attenuating systems, applying them in the structures is proportional to following complicated technology and subtle engineering. Furthermore, installation and initiation of this systems depend on educated and expert crews and such attenuating systems need maintenance and repair during the useful structural life time. The aforementioned reasons lead to limitation and high-cost of utilizing such system especially in developing countries. Consequently, nowadays civil engineering suffers from the lack of such quake-attenuating systems to be able to respond simply but applicable mechanism at the same time for almost all types of structure.

Earthquake Resistance System

Nowadays civil engineering suffers from the lack of such quake-attenuating systems to be able to respond simply but applicable mechanism at the same time for almost all types of structure. Inspired by Patent No.: US 6,862,848B1, year 2008 Tsang published an article and introduced new system of isolation (Tsang 2008). This system is formed from rubber and soil mixture located in the base ground under structure foundation. Tsang showed the ability of mitigation of earthquake energy and isolation wave transition of this system for a ten story building. Afterward Kaneko conducted pseudo-dynamic response test and concluded that this system is effective for both seismic isolation and to prevent liquefaction and Xiong proposed that seismic isolation per-formance of rubber soil mixture is inferior to that of a foundation underlain by pure-sand, carried out by shak-ing table tests with a 1/3 scale rubbersoil mixtures model. All these evaluations prove the isolation ability of rubber-soil mixture as an isolator system. Therefore, researches over this new idea has begun and researches such as Senetakis et al. has started to find the behavioral parameters of rubber-soil mixture

Geo-Isolator Advantages

Geo-isolator is a new isolation system, which is located in the ground under the foundation. This system mit-igates earthquake peak acceleration such that for the worst case of ground 0.7g excitation, isolated structure experiences 0.35g peak acceleration. Results of this research are offered in the form of design spectra, by evaluating seven scaled excitations soil response analyses. The important outcomes of this research are as follow: