Civil Engineering Team

A leader in the design and implementation of the latest and the most innovative engineering methods

Underground Structures and Earthquakes

In 1989, the Loma Prieta earthquake had devastating effects on San Franciscos city and transportation systems. It led to the destruction of the urban railway tunnel, significant damage and disruption to surface transportation, and the disconnection of the citys communication bridge. Remarkably, the BART subway system remained operational, providing the only means of connecting the city with the outside world post-earthquake.

The resilience of the BART tunnel was attributed to the foresight of structural design engineers who had incorporated seismic criteria into the tunnels design. This event underscored the critical importance of foresight and the application of seismic controls in the design of essential infrastructure. Consequently, from that year onwards, engineers have focused on investigating and developing vibration control criteria for underground structures.

Underground Structures

Underground structures refer to spaces created beneath the earths surface for various purposes such as passage, communication, and protection. These include road tunnels, subways, canals, storage tanks, and shelters. With advancements in technology, it is now possible to construct tunnels and other underground structures in diverse geological conditions beneath large cities.

Underground tunnels serve as vital arteries and communication lines for urban communities. This includes subway lines, canals, water pipes, sewers, oil and gas pipelines, telecommunication, and electricity cable ducts. All these elements are essential for the survival of modern urban populations. However, the transformation of these spaces into critical infrastructure also increases their vulnerability, making potential damage more impactful.

Tunnels require a higher level of safety compared to other structures like dams because even minor damage can cause significant harm over a large urban area. Historical earthquake data shows that underground structures generally suffer less damage than above-ground structures. However, recent earthquakes, such as those in Kobe, Japan, and Chi-Chi, Taiwan (1995), have caused significant damage to underground structures, highlighting the need for ongoing research and the development of new methods for designing and constructing underground structures to withstand dynamic earthquake loads.

Performance of Underground Structures Against Earthquakes

The performance of underground structures during earthquakes is complex. Historically, tunnel designers have considered underground structures to be among the safest shelters during earthquakes, based on damage statistics from past events. However, it is crucial that these spaces are designed with seismic considerations in mind.

Most existing tunnels were constructed without accounting for seismic effects, as seismic design was historically less emphasized for underground structures compared to above-ground ones. This was largely due to the perceived reliability of these structures. Seismic design for underground spaces began to be considered in the 1960s. In recent years, increased awareness of seismic hazards has led to a better understanding of the factors affecting the seismic behavior of underground structures.

The 1989 Loma Prieta earthquake in San Francisco had severe impacts on the citys transportation system, including the collapse of a railroad bridge, resulting in over 40 deaths, and causing approximately two billion dollars in damage to transportation infrastructure. It also disrupted communication routes, particularly the San Francisco-Oakland bridge. Remarkably, San Franciscos subway system remained one of the safest places during the disaster and served as the citys only transportation link post-earthquake. This resilience was due to the foresight of engineers who, thirty years prior, had incorporated seismic design criteria into the subway tunnel plans. The value of this foresight was proven by the earthquakes occurrence.

The Difference Between Underground and Surface Structures

One of the key distinguishing features of surface structures is their transmission path and connection to the point where energy enters. This means that the connection of surface structures to the foundation bed and surrounding soil facilitates the transmission of incoming dynamic waves. Compared to underground structures, surface structures have less strength at the point of power transmission. As a result, surface structures often require increased capacity to withstand dynamic forces, with the need for capacity enhancement typically ranging between 30% and 70%.

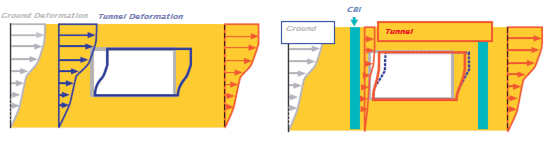

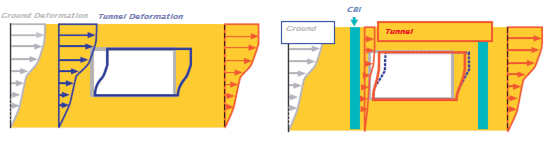

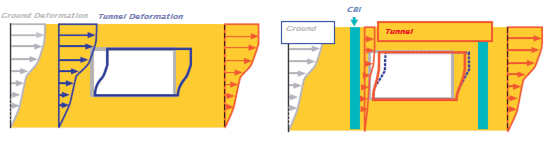

In contrast, underground structures are fully influenced by their surrounding environment and follow the movement patterns of the surrounding ground. Unlike surface structures, which are supported only at the base, underground structures are significantly surrounded by soil at depth, providing a higher degree of support.

Due to these differences, underground structures are designed differently from surface structures. For surface structures, earthquake loads are applied as inertial forces, whereas for underground structures, analysis and design are based on the deformation of both the structure and the surrounding soil. This is because underground structures are subject to environmental changes, making earthquake force an unsuitable measure for them.

Underground structures have unique features that set them apart from other structures. These include being buried in the soil, having a considerably large length compared to other dimensions, possessing a high degree of grip, and adapting to changes in the surrounding environment.

Another important difference between these two types of structures is the dynamic design of seismic effects in underground structures. While static design can often control the overall design of underground tunnels, the science of investigating seismic wave effects on underground structures is relatively new, dating back to the 1990s. It was during this decade that the first written report on the seismic investigation of tunnels was presented. Although static design provides good reliability for tunnel design, the critical role of these communication highways means that even minor damage leading to performance disruption can result in significant disasters.

Design of Underground Structures

Historical reviews of earthquakes show that underground structures generally sustain less damage compared to surface structures. However, recent earthquakes have caused significant damage to underground structures, prompting revisions and strengthening efforts. This highlights the inevitable need for further research and the development of new methods for designing and implementing underground structures to withstand the dynamic loading of earthquake waves.

In underground structures, static design can effectively control dynamic vibrations. However, damage to the tunnel body can result in significantly higher costs. Therefore, the investigation and dynamic design of underground structures are crucial. Design records indicate that underground structures are less vulnerable to ground vibrations than surface structures. Nonetheless, the 1995 Hyogoken-Nambu earthquake in Japan caused severe damage to some underground stations, despite causing more extensive damage to surface structures.

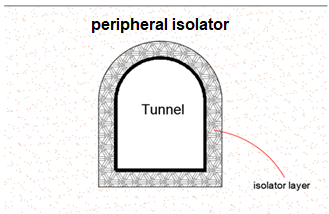

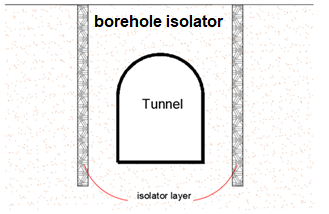

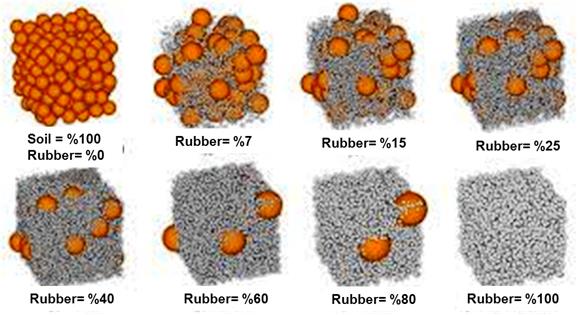

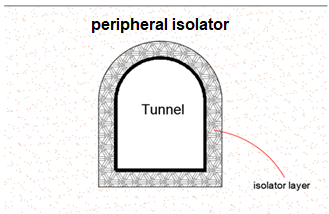

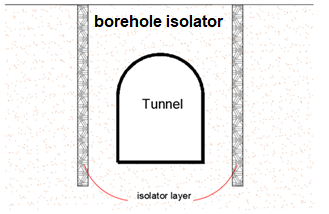

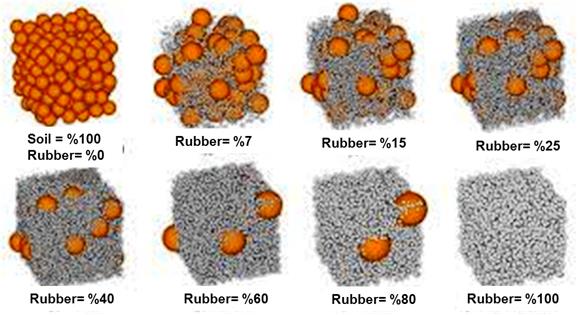

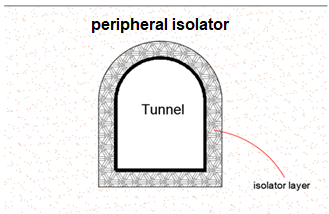

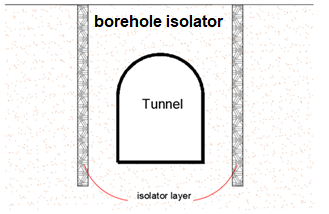

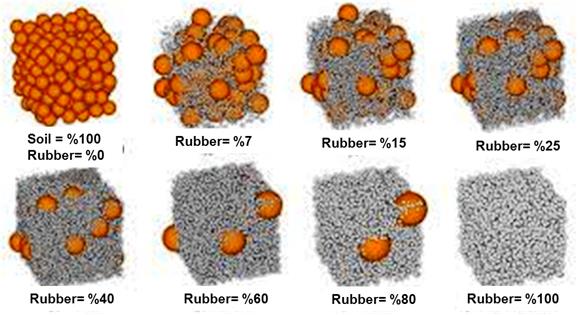

Reinforcing the lateral bearing system, which is effective in surface structures, is not as effective in underground structures. Increasing the rigidity of an underground structure enhances its resistance to environmental changes, allowing it to bear greater dynamic forces. Therefore, the best way to strengthen underground structures is to make the body flexible (e.g., reducing concrete thickness and using additional reinforcement) or to isolate the body from the surrounding environment using isolation systems. This does not mean that surface structure reinforcement systems are inapplicable to underground structures, but the design and implementation costs for such measures are often unjustified.

Underground Structures and Earthquakes

In 1989, the Loma Prieta earthquake had devastating effects on San Franciscos city and transportation systems. It led to the destruction of the urban railway tunnel, significant damage and disruption to surface transportation, and the disconnection of the citys communication bridge. Remarkably, the BART subway system remained operational, providing the only means of connecting the city with the outside world post-earthquake.

The resilience of the BART tunnel was attributed to the foresight of structural design engineers who had incorporated seismic criteria into the tunnels design. This event underscored the critical importance of foresight and the application of seismic controls in the design of essential infrastructure. Consequently, from that year onwards, engineers have focused on investigating and developing vibration control criteria for underground structures.

Underground Structures

Underground structures refer to spaces created beneath the earths surface for various purposes such as passage, communication, and protection. These include road tunnels, subways, canals, storage tanks, and shelters. With advancements in technology, it is now possible to construct tunnels and other underground structures in diverse geological conditions beneath large cities.

Underground tunnels serve as vital arteries and communication lines for urban communities. This includes subway lines, canals, water pipes, sewers, oil and gas pipelines, telecommunication, and electricity cable ducts. All these elements are essential for the survival of modern urban populations. However, the transformation of these spaces into critical infrastructure also increases their vulnerability, making potential damage more impactful.

Tunnels require a higher level of safety compared to other structures like dams because even minor damage can cause significant harm over a large urban area. Historical earthquake data shows that underground structures generally suffer less damage than above-ground structures. However, recent earthquakes, such as those in Kobe, Japan, and Chi-Chi, Taiwan (1995), have caused significant damage to underground structures, highlighting the need for ongoing research and the development of new methods for designing and constructing underground structures to withstand dynamic earthquake loads.

Performance of Underground Structures Against Earthquakes

The performance of underground structures during earthquakes is complex. Historically, tunnel designers have considered underground structures to be among the safest shelters during earthquakes, based on damage statistics from past events. However, it is crucial that these spaces are designed with seismic considerations in mind.

Most existing tunnels were constructed without accounting for seismic effects, as seismic design was historically less emphasized for underground structures compared to above-ground ones. This was largely due to the perceived reliability of these structures. Seismic design for underground spaces began to be considered in the 1960s. In recent years, increased awareness of seismic hazards has led to a better understanding of the factors affecting the seismic behavior of underground structures.

The 1989 Loma Prieta earthquake in San Francisco had severe impacts on the citys transportation system, including the collapse of a railroad bridge, resulting in over 40 deaths, and causing approximately two billion dollars in damage to transportation infrastructure. It also disrupted communication routes, particularly the San Francisco-Oakland bridge. Remarkably, San Franciscos subway system remained one of the safest places during the disaster and served as the citys only transportation link post-earthquake. This resilience was due to the foresight of engineers who, thirty years prior, had incorporated seismic design criteria into the subway tunnel plans. The value of this foresight was proven by the earthquakes occurrence.

The Difference Between Underground and Surface Structures

One of the key distinguishing features of surface structures is their transmission path and connection to the point where energy enters. This means that the connection of surface structures to the foundation bed and surrounding soil facilitates the transmission of incoming dynamic waves. Compared to underground structures, surface structures have less strength at the point of power transmission. As a result, surface structures often require increased capacity to withstand dynamic forces, with the need for capacity enhancement typically ranging between 30% and 70%.

In contrast, underground structures are fully influenced by their surrounding environment and follow the movement patterns of the surrounding ground. Unlike surface structures, which are supported only at the base, underground structures are significantly surrounded by soil at depth, providing a higher degree of support.

Due to these differences, underground structures are designed differently from surface structures. For surface structures, earthquake loads are applied as inertial forces, whereas for underground structures, analysis and design are based on the deformation of both the structure and the surrounding soil. This is because underground structures are subject to environmental changes, making earthquake force an unsuitable measure for them.

Underground structures have unique features that set them apart from other structures. These include being buried in the soil, having a considerably large length compared to other dimensions, possessing a high degree of grip, and adapting to changes in the surrounding environment.

Another important difference between these two types of structures is the dynamic design of seismic effects in underground structures. While static design can often control the overall design of underground tunnels, the science of investigating seismic wave effects on underground structures is relatively new, dating back to the 1990s. It was during this decade that the first written report on the seismic investigation of tunnels was presented. Although static design provides good reliability for tunnel design, the critical role of these communication highways means that even minor damage leading to performance disruption can result in significant disasters.

Design of Underground Structures

Historical reviews of earthquakes show that underground structures generally sustain less damage compared to surface structures. However, recent earthquakes have caused significant damage to underground structures, prompting revisions and strengthening efforts. This highlights the inevitable need for further research and the development of new methods for designing and implementing underground structures to withstand the dynamic loading of earthquake waves.

In underground structures, static design can effectively control dynamic vibrations. However, damage to the tunnel body can result in significantly higher costs. Therefore, the investigation and dynamic design of underground structures are crucial. Design records indicate that underground structures are less vulnerable to ground vibrations than surface structures. Nonetheless, the 1995 Hyogoken-Nambu earthquake in Japan caused severe damage to some underground stations, despite causing more extensive damage to surface structures.

Reinforcing the lateral bearing system, which is effective in surface structures, is not as effective in underground structures. Increasing the rigidity of an underground structure enhances its resistance to environmental changes, allowing it to bear greater dynamic forces. Therefore, the best way to strengthen underground structures is to make the body flexible (e.g., reducing concrete thickness and using additional reinforcement) or to isolate the body from the surrounding environment using isolation systems. This does not mean that surface structure reinforcement systems are inapplicable to underground structures, but the design and implementation costs for such measures are often unjustified.

Underground Structures and Earthquakes

In 1989, the Loma Prieta earthquake had devastating effects on San Franciscos city and transportation systems. It led to the destruction of the urban railway tunnel, significant damage and disruption to surface transportation, and the disconnection of the citys communication bridge. Remarkably, the BART subway system remained operational, providing the only means of connecting the city with the outside world post-earthquake.

The resilience of the BART tunnel was attributed to the foresight of structural design engineers who had incorporated seismic criteria into the tunnels design. This event underscored the critical importance of foresight and the application of seismic controls in the design of essential infrastructure. Consequently, from that year onwards, engineers have focused on investigating and developing vibration control criteria for underground structures.

Underground Structures

Underground structures refer to spaces created beneath the earths surface for various purposes such as passage, communication, and protection. These include road tunnels, subways, canals, storage tanks, and shelters. With advancements in technology, it is now possible to construct tunnels and other underground structures in diverse geological conditions beneath large cities.

Underground tunnels serve as vital arteries and communication lines for urban communities. This includes subway lines, canals, water pipes, sewers, oil and gas pipelines, telecommunication, and electricity cable ducts. All these elements are essential for the survival of modern urban populations. However, the transformation of these spaces into critical infrastructure also increases their vulnerability, making potential damage more impactful.

Tunnels require a higher level of safety compared to other structures like dams because even minor damage can cause significant harm over a large urban area. Historical earthquake data shows that underground structures generally suffer less damage than above-ground structures. However, recent earthquakes, such as those in Kobe, Japan, and Chi-Chi, Taiwan (1995), have caused significant damage to underground structures, highlighting the need for ongoing research and the development of new methods for designing and constructing underground structures to withstand dynamic earthquake loads.

Performance of Underground Structures Against Earthquakes

The performance of underground structures during earthquakes is complex. Historically, tunnel designers have considered underground structures to be among the safest shelters during earthquakes, based on damage statistics from past events. However, it is crucial that these spaces are designed with seismic considerations in mind.

Most existing tunnels were constructed without accounting for seismic effects, as seismic design was historically less emphasized for underground structures compared to above-ground ones. This was largely due to the perceived reliability of these structures. Seismic design for underground spaces began to be considered in the 1960s. In recent years, increased awareness of seismic hazards has led to a better understanding of the factors affecting the seismic behavior of underground structures.

The 1989 Loma Prieta earthquake in San Francisco had severe impacts on the citys transportation system, including the collapse of a railroad bridge, resulting in over 40 deaths, and causing approximately two billion dollars in damage to transportation infrastructure. It also disrupted communication routes, particularly the San Francisco-Oakland bridge. Remarkably, San Franciscos subway system remained one of the safest places during the disaster and served as the citys only transportation link post-earthquake. This resilience was due to the foresight of engineers who, thirty years prior, had incorporated seismic design criteria into the subway tunnel plans. The value of this foresight was proven by the earthquakes occurrence.

The Difference Between Underground and Surface Structures

One of the key distinguishing features of surface structures is their transmission path and connection to the point where energy enters. This means that the connection of surface structures to the foundation bed and surrounding soil facilitates the transmission of incoming dynamic waves. Compared to underground structures, surface structures have less strength at the point of power transmission. As a result, surface structures often require increased capacity to withstand dynamic forces, with the need for capacity enhancement typically ranging between 30% and 70%.

In contrast, underground structures are fully influenced by their surrounding environment and follow the movement patterns of the surrounding ground. Unlike surface structures, which are supported only at the base, underground structures are significantly surrounded by soil at depth, providing a higher degree of support.

Due to these differences, underground structures are designed differently from surface structures. For surface structures, earthquake loads are applied as inertial forces, whereas for underground structures, analysis and design are based on the deformation of both the structure and the surrounding soil. This is because underground structures are subject to environmental changes, making earthquake force an unsuitable measure for them.

Underground structures have unique features that set them apart from other structures. These include being buried in the soil, having a considerably large length compared to other dimensions, possessing a high degree of grip, and adapting to changes in the surrounding environment.

Another important difference between these two types of structures is the dynamic design of seismic effects in underground structures. While static design can often control the overall design of underground tunnels, the science of investigating seismic wave effects on underground structures is relatively new, dating back to the 1990s. It was during this decade that the first written report on the seismic investigation of tunnels was presented. Although static design provides good reliability for tunnel design, the critical role of these communication highways means that even minor damage leading to performance disruption can result in significant disasters.

Design of Underground Structures

Historical reviews of earthquakes show that underground structures generally sustain less damage compared to surface structures. However, recent earthquakes have caused significant damage to underground structures, prompting revisions and strengthening efforts. This highlights the inevitable need for further research and the development of new methods for designing and implementing underground structures to withstand the dynamic loading of earthquake waves.

In underground structures, static design can effectively control dynamic vibrations. However, damage to the tunnel body can result in significantly higher costs. Therefore, the investigation and dynamic design of underground structures are crucial. Design records indicate that underground structures are less vulnerable to ground vibrations than surface structures. Nonetheless, the 1995 Hyogoken-Nambu earthquake in Japan caused severe damage to some underground stations, despite causing more extensive damage to surface structures.

Reinforcing the lateral bearing system, which is effective in surface structures, is not as effective in underground structures. Increasing the rigidity of an underground structure enhances its resistance to environmental changes, allowing it to bear greater dynamic forces. Therefore, the best way to strengthen underground structures is to make the body flexible (e.g., reducing concrete thickness and using additional reinforcement) or to isolate the body from the surrounding environment using isolation systems. This does not mean that surface structure reinforcement systems are inapplicable to underground structures, but the design and implementation costs for such measures are often unjustified.