Civil Engineering Team

A leader in the design and implementation of the latest and the most innovative engineering methods

Export

We are a group of structural engineers who have been working for many years in designing and constructing buildings with different applications in Iran. Based on the experiences we have gained, we decided to extend our field of activity to neighboring countries and export designed and constructed structures that can be prefabricated.

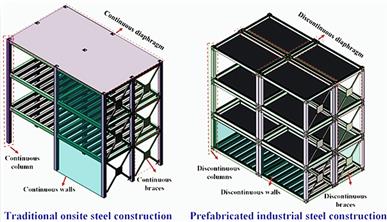

Compared to traditional on-site steel construction, prefab industrial steel construction saves time, money, and resources. This results in the use of fewer resources and is better for the environment.

Based on this, we designed and implemented the industrial production process of prefabricated steel structures. The methods used in the design and construction process are very precise and based on international regulations and standards that match the regulations of the destination countries.

The design is based on computer modeling using the most advanced design software. The required steel sections are procured from large and reliable factories in Iran. Afterward, the process of making the structure is completed in the factory, while quality control tests are performed at every stage.

The documentation of all the design stages, including the computer modeling, structure plans, laboratory reports, and the specifications and strength of the steel are prepared and sent to the client along with the quality control tests of the manufacturing process. As a result, the quality of all stages of design and construction is guaranteed for the employer.

Prefabricated Steel Structure (PSS)

Prefab Steel Structures (PSS) have considerable technical and operational advantages over conventional steel and concrete structures. The SET experienced engineers use new methods of structure design in accordance with the universal codes and standards which reduce the cost and make the PSS more economical. Consequently, PSS is a suitable and better alternative for the structure of buildings. Some advantages of the PSS are as follows:

Optimization of Structure Design

Export

We are a group of structural engineers who have been working for many years in designing and constructing buildings with different applications in Iran. Based on the experiences we have gained, we decided to extend our field of activity to neighboring countries and export designed and constructed structures that can be prefabricated.

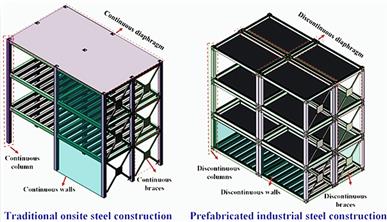

Compared to traditional on-site steel construction, prefab industrial steel construction saves time, money, and resources. This results in the use of fewer resources and is better for the environment.

Based on this, we designed and implemented the industrial production process of prefabricated steel structures. The methods used in the design and construction process are very precise and based on international regulations and standards that match the regulations of the destination countries.

The design is based on computer modeling using the most advanced design software. The required steel sections are procured from large and reliable factories in Iran. Afterward, the process of making the structure is completed in the factory, while quality control tests are performed at every stage.

The documentation of all the design stages, including the computer modeling, structure plans, laboratory reports, and the specifications and strength of the steel are prepared and sent to the client along with the quality control tests of the manufacturing process. As a result, the quality of all stages of design and construction is guaranteed for the employer.

Export

We are a group of structural engineers who have been working for many years in designing and constructing buildings with different applications in Iran. Based on the experiences we have gained, we decided to extend our field of activity to neighboring countries and export designed and constructed structures that can be prefabricated.

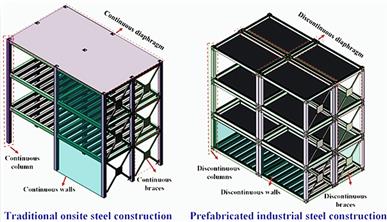

Compared to traditional on-site steel construction, prefab industrial steel construction saves time, money, and resources. This results in the use of fewer resources and is better for the environment.

Based on this, we designed and implemented the industrial production process of prefabricated steel structures. The methods used in the design and construction process are very precise and based on international regulations and standards that match the regulations of the destination countries.

The design is based on computer modeling using the most advanced design software. The required steel sections are procured from large and reliable factories in Iran. Afterward, the process of making the structure is completed in the factory, while quality control tests are performed at every stage.

The documentation of all the design stages, including the computer modeling, structure plans, laboratory reports, and the specifications and strength of the steel are prepared and sent to the client along with the quality control tests of the manufacturing process. As a result, the quality of all stages of design and construction is guaranteed for the employer.

Prefabricated Steel Structure (PSS)

Prefab Steel Structures (PSS) have considerable technical and operational advantages over conventional steel and concrete structures. The SET experienced engineers use new methods of structure design in accordance with the universal codes and standards which reduce the cost and make the PSS more economical. Consequently, PSS is a suitable and better alternative for the structure of buildings. Some advantages of the PSS are as follows:

Optimization of Structure Design

Prefabricated Steel Structure (PSS)

Prefab Steel Structures (PSS) have considerable technical and operational advantages over conventional steel and concrete structures. The SET experienced engineers use new methods of structure design in accordance with the universal codes and standards which reduce the cost and make the PSS more economical. Consequently, PSS is a suitable and better alternative for the structure of buildings. Some advantages of the PSS are as follows:

Optimization of Structure Design