Civil Engineering Team

A leader in the design and implementation of the latest and the most innovative engineering methods

Apam-Napat Submersible

Underwater Manned Mini-Sub

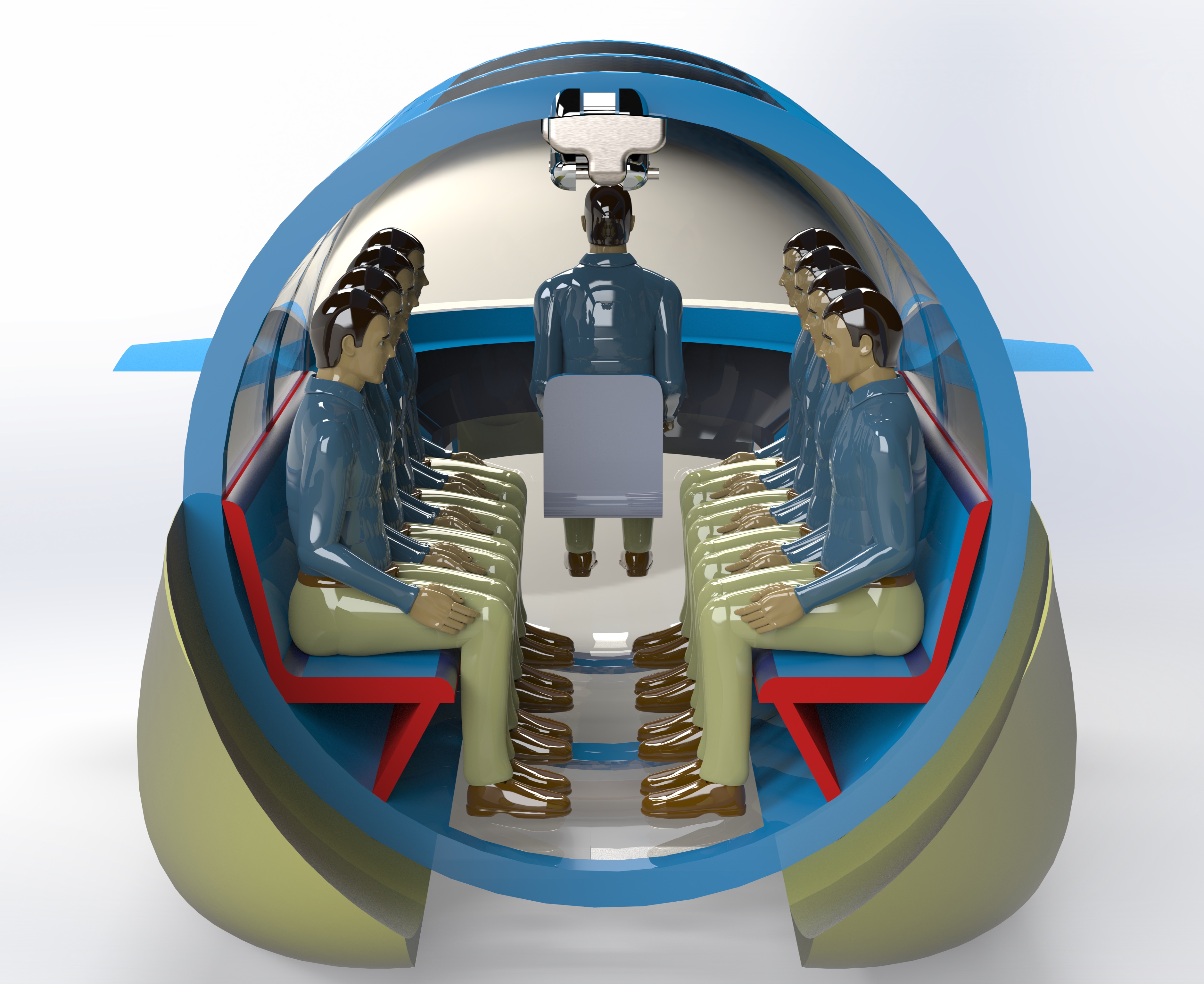

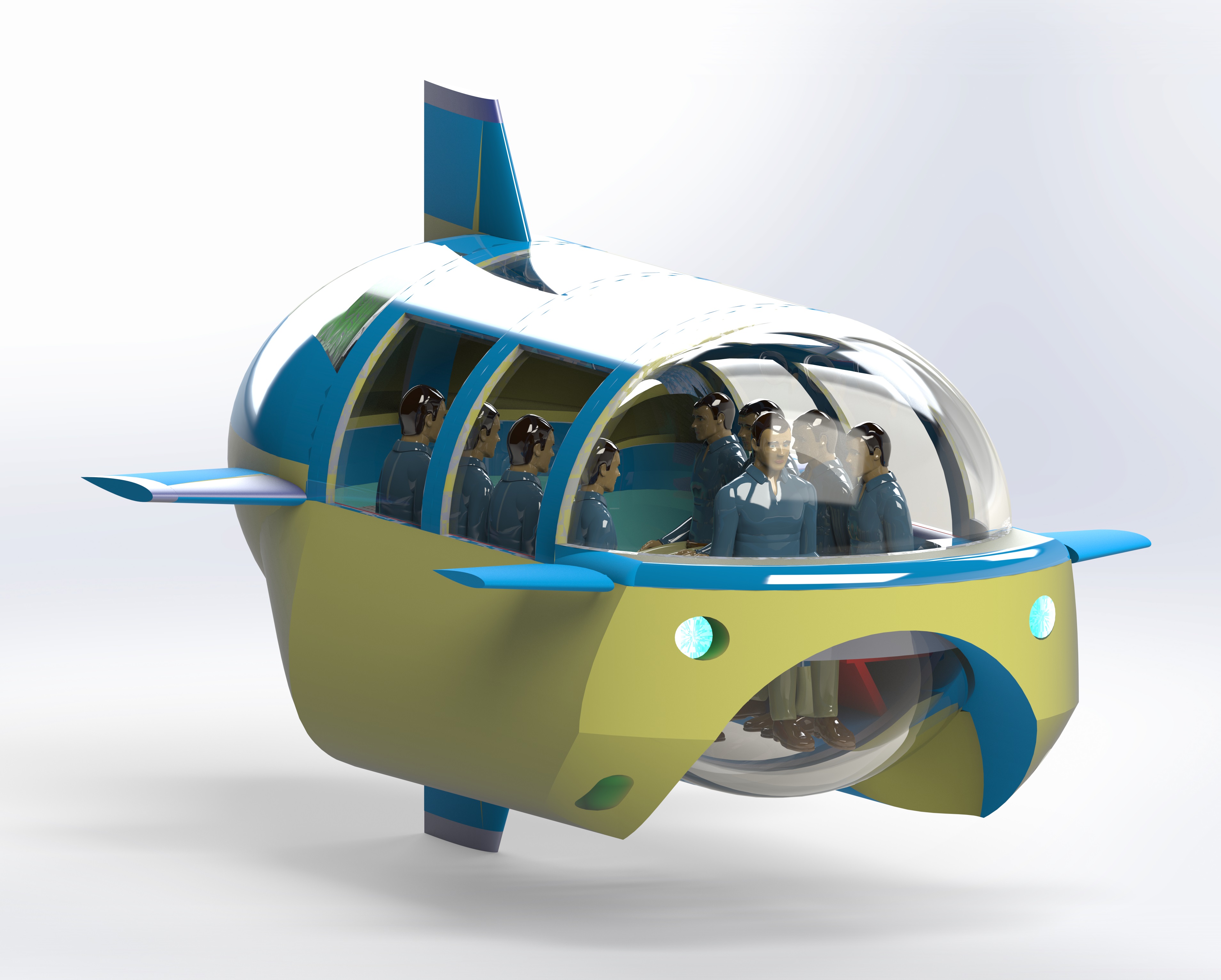

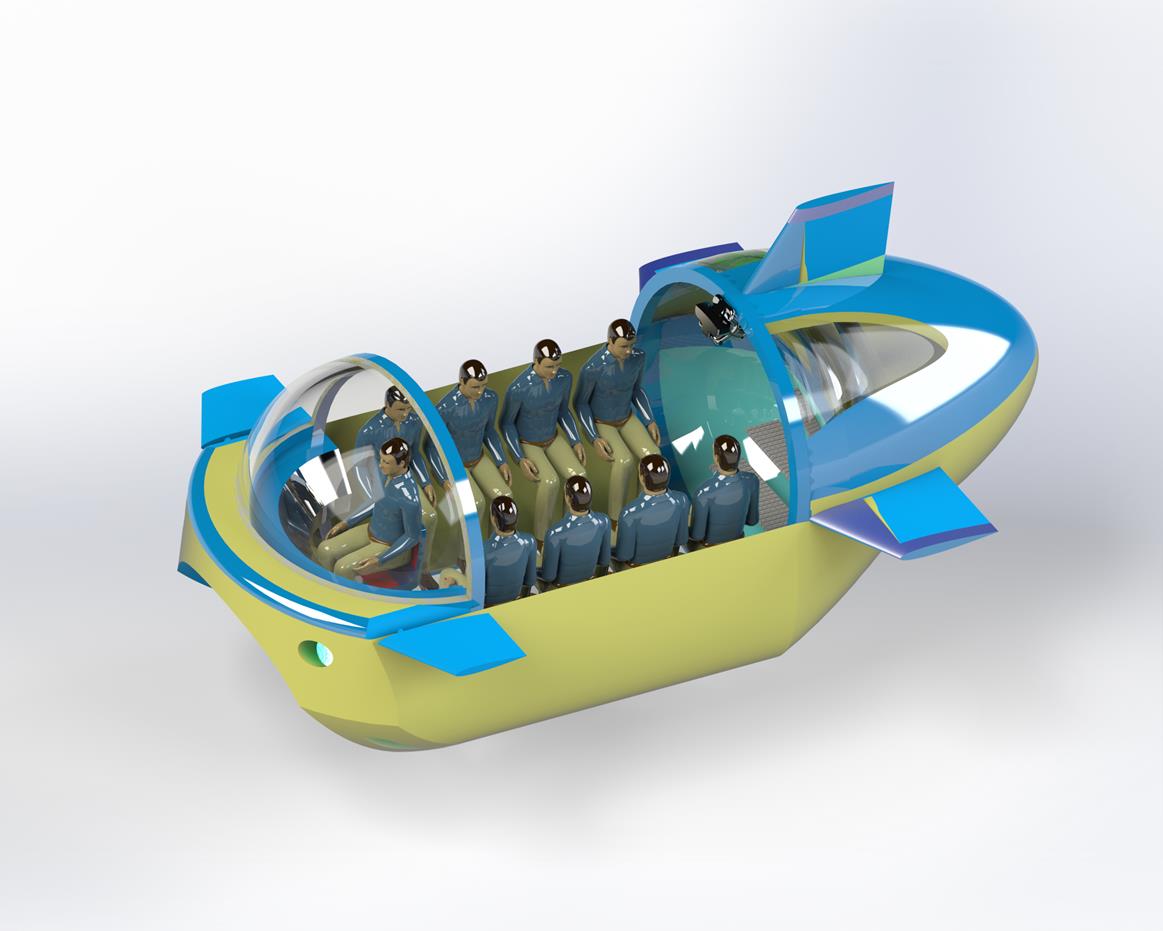

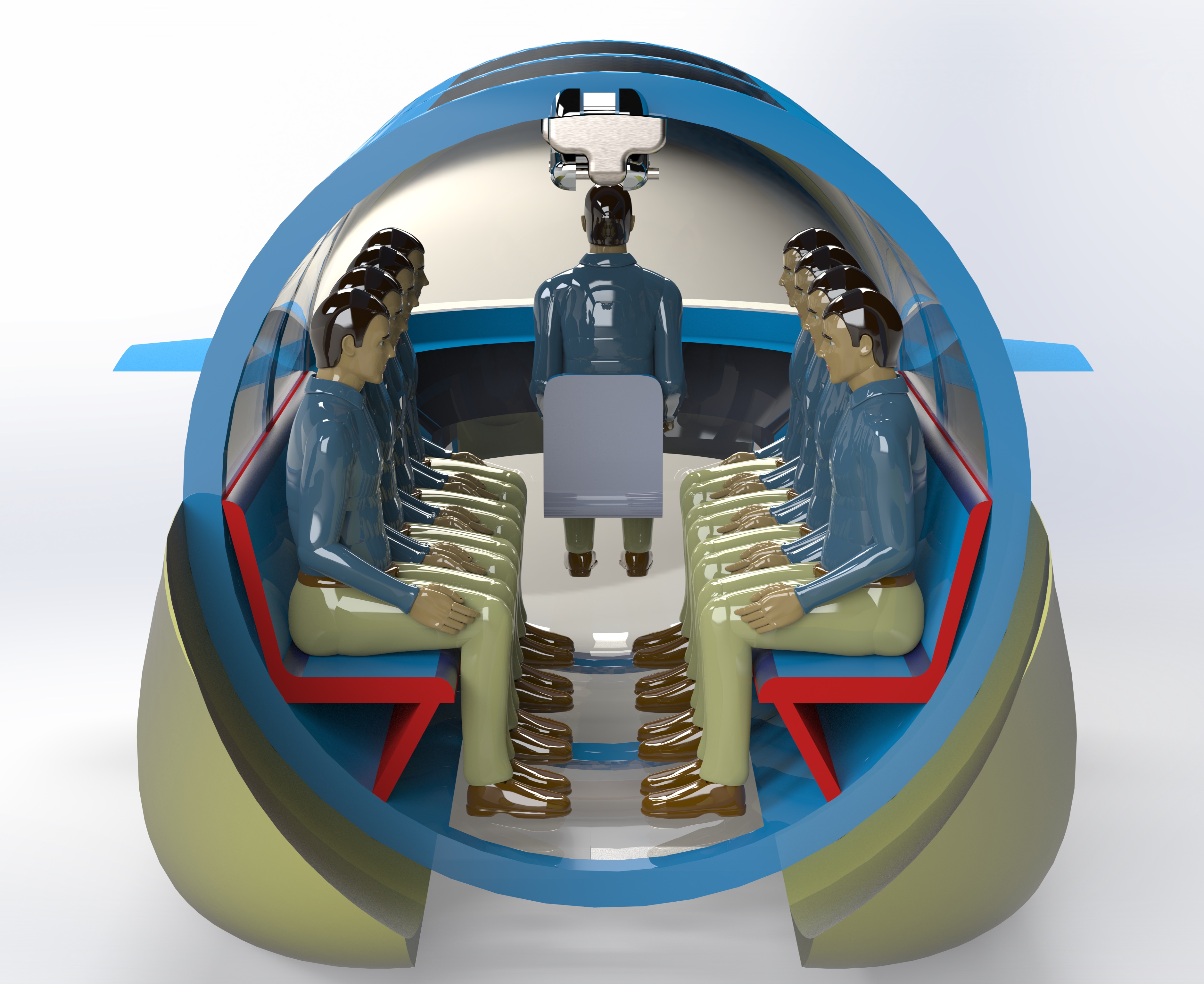

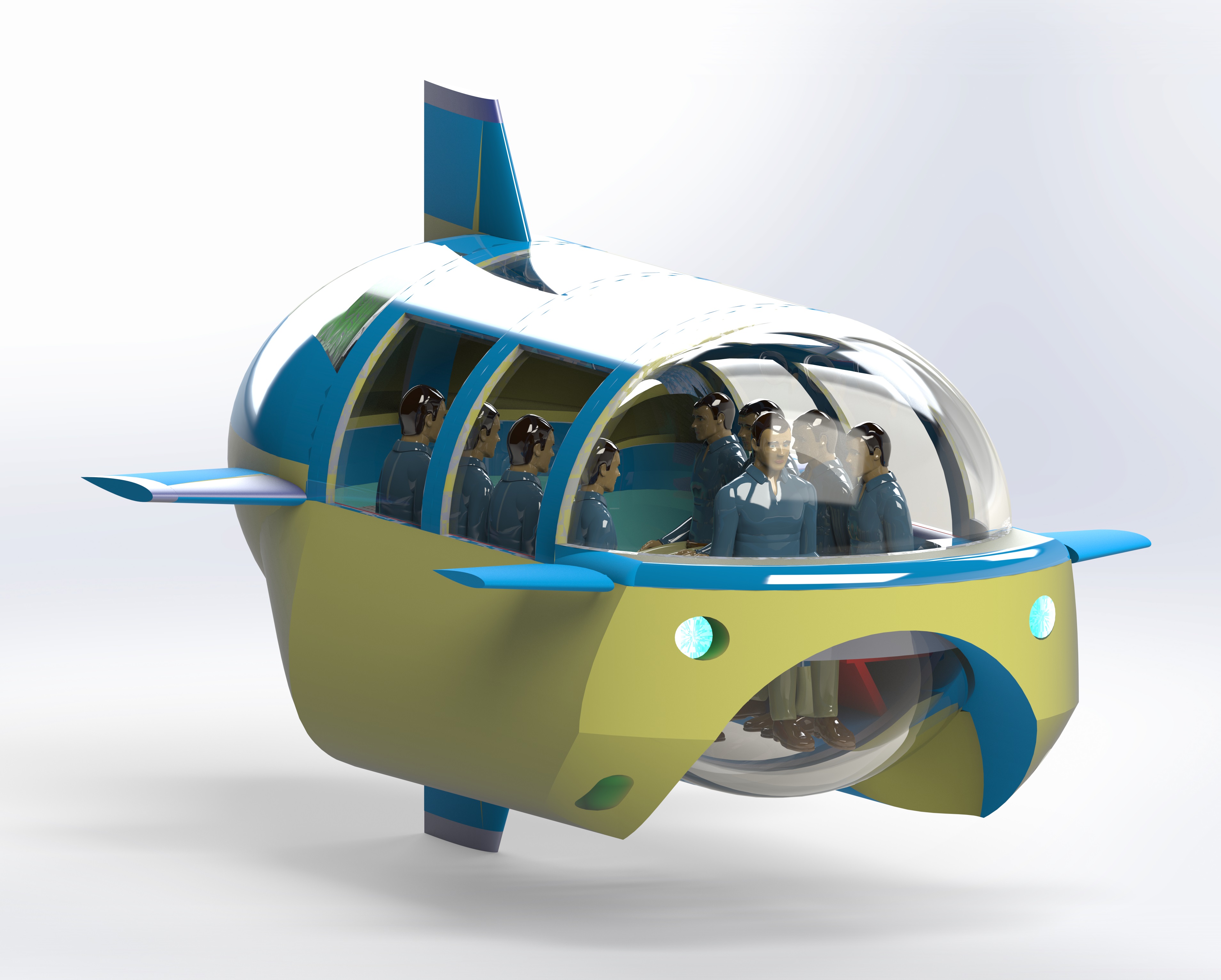

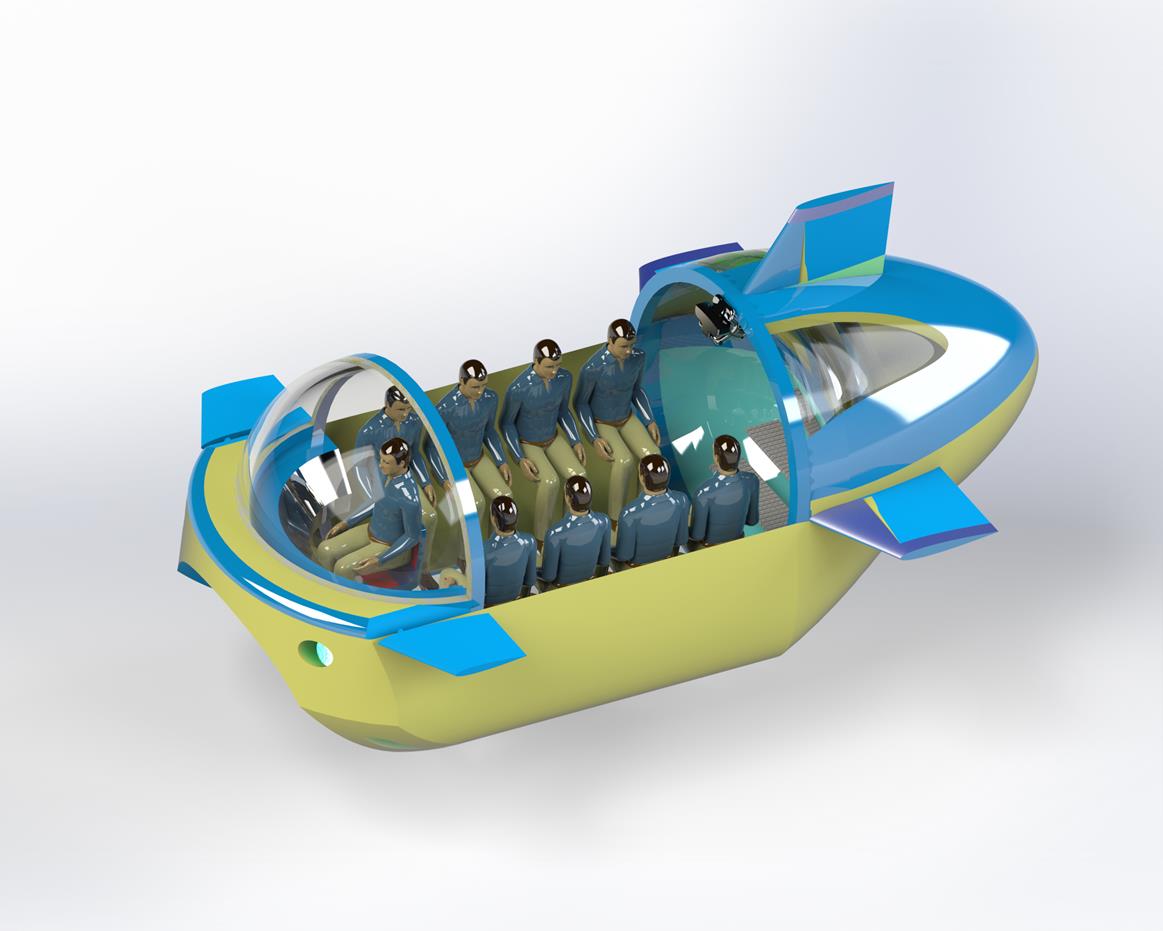

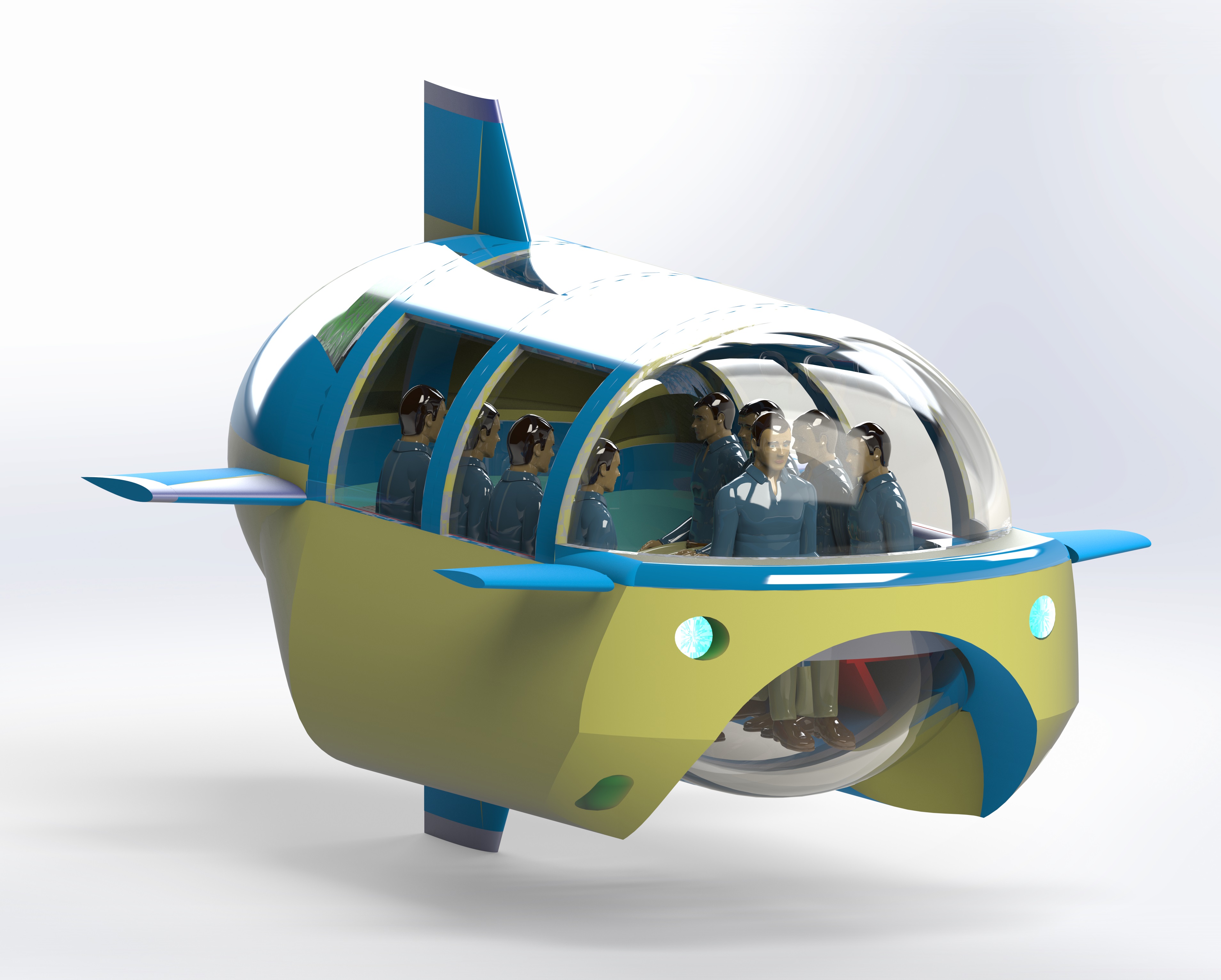

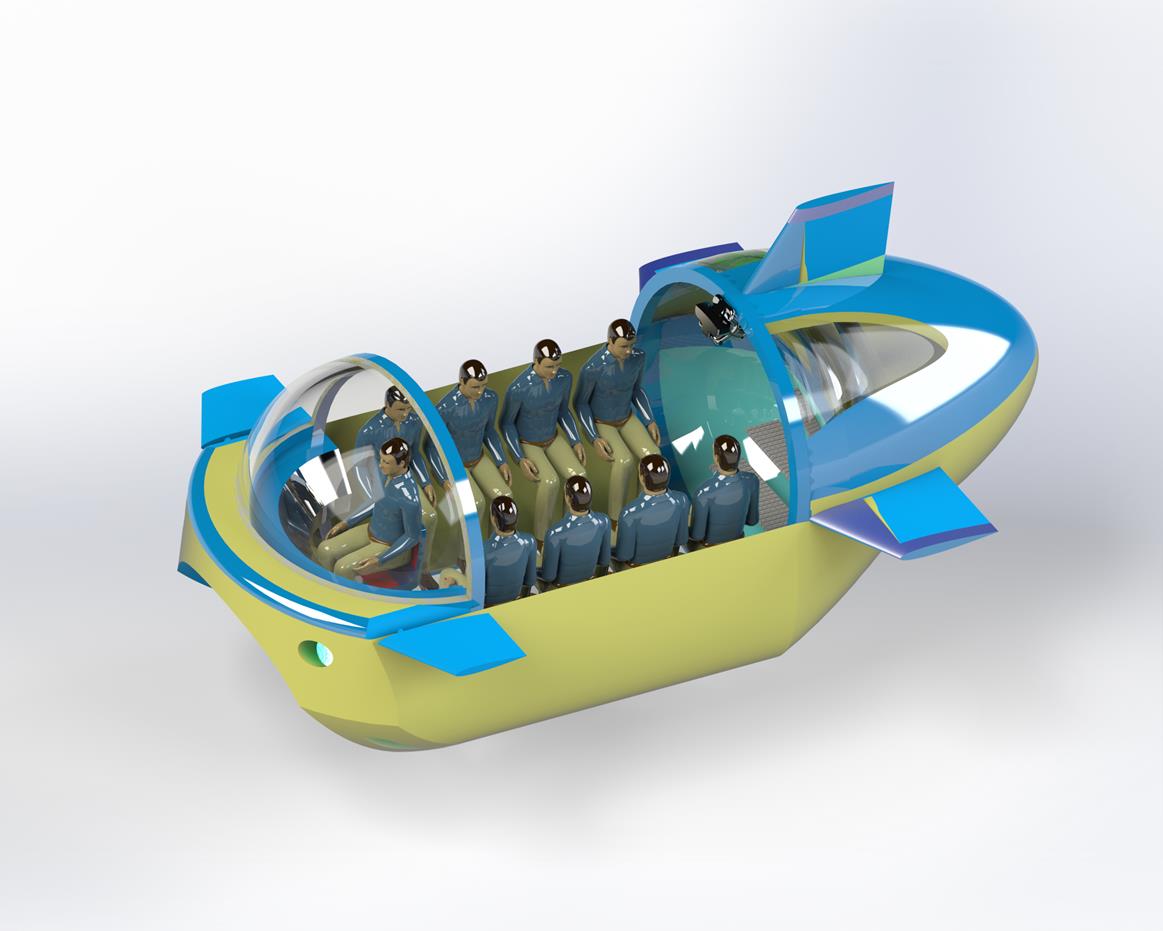

Humans have always been fascinated by the underwater world and inspired to find new ways to explore it. Submarines are limited for public use due to military classification issues and being expensive. This page introduces a new squat submarine. This squat submarine has 9-person capacity as a manned midget submersible using specific geometries of length-over-depth ratios (L/D) below four (Sarraf et al. 2022). The cause of such selection is to provide better visibility for the passengers to research and explore the sea. However, the geometrical features considerably change the hydrodynamic performance of the submarine, for example, by causing pressure drag. This submarine hull is equipped with a hemisphere bow with a cylindrical middle body to provide more vision for the passengers for research and tourist purposes.

Optimal Operation, High Standard, Great Safety

ICE presents a new midget submarine (mini-submarine) with the ability for independent movement, lightweight, and up to 9-person capacity. This type of submarine has attracted considerable focus over recent years, and some commercial factories are also working in this field. The naval submarine design science aims to find the best-suited shape for the vessel to provide better hydrodynamic functionality and extend the range and time of the operation by decreasing the energy demand needed for the movement of the vessel. In fact, submarines encounter limited energy on the surface and submerged navigation; therefore, the minimum resistance is vital in the submarine hydrodynamic design. A body shape with a suitable hydrodynamic condition can reduce drag effects on the hull to minimize the operational energy demand. Consequently, the Apam-Napat submersible is design in order to operate in a complete optimized way. The design went through a number of iterations before it reached its current optimum state.

It took considerable time and effort to reach the current design status that we believe to be absolutely optimum. An emplacement depth range of from 20 meters provides significant versatility of site location and the modular nature of the design means later expansion or the development of larger or smaller submarine is simple.

In this submarine, there has never been a serious injury or fatality to any passenger aboard an ABS classed submarine or submersible. Our intention is to build the Apam-Napat submersible to the rigorous safety standards we apply to submarine projects and to have the standards and implementation verified by outside engineering experts that report to the insurance underwriters. The design specifications generally follow the requirements of such regulations as proposed in Rules for Building and Classing Underwater Systems and Vehicles by the Iranian Society of Safety Standard for Pressure Vessels for Human Occupancy. In fact, we are taking the principals, materials, techniques and structures from what has been demonstrated to be the worlds safest form of transportation and utilizing them to build a submarine structure that is considerably safer.

The submarine has been designed specifically to have a net positive impact on the environment. Apam-Napat submersible most important environmental effect will be to introduce thousands of people to the sub-sea world and to promote environmental stewardship, for you can only expect people to act to protect the marine environment if they understand the issues and can see what they are protecting first-hand. We are committed to environmental sensitivity and stewardship..

Operational mechanism

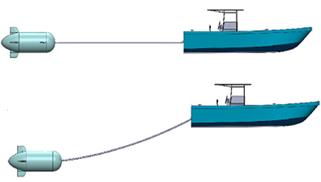

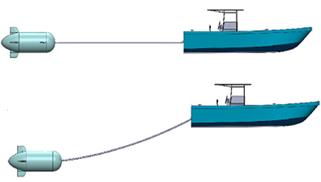

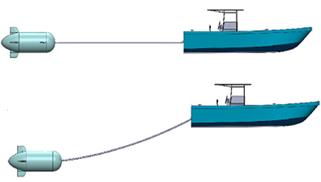

The submarine is towed by a ship between the port and desired locations. It is then launched from the ship to operate independently at the intended location. Alternatively, the submarine can stay connected to the ship and be towed throughout the operation. The towing function provides simple operational mechanisms, low-cost operation and maintenance, and higher operational time. The towing function provides a simpler, less noisy, and lower-cost operation at site, while allowing higher operational time.

This arrangement can be used for exploration, research, maintenance, and tourist attractions. Originally, the idea of towing a manned underwater vehicle was patented by Green (1962). The vehicle consisted of an open hull with a tapered rear end design to carry a diver inside. In the present study, a squat submarine is used, which is of Apam-Napat SMSD type introduced by Sarraf et al. (2022). This submarine is a manned midget submersible with a 9-person capacity using specific length-over-depth (L/D) ratios below four, contrary to conventional submarines which use higher L/D ratios (Moonesun and Korol 2017, Arentzen and Mandel 1960, Sarraf et al. 2022). The cause of such selection is to provide better visibility for the passengers to research and explore the sea. This geometric feature is in contrast to conventional submarines that are designed to be efficient at high velocities and to remain undetected. In addition, this towed submarine eliminates the need for a propulsion system and fuel carrying. L/D ratios below four considerably change the hydrodynamic performance of the vessels.

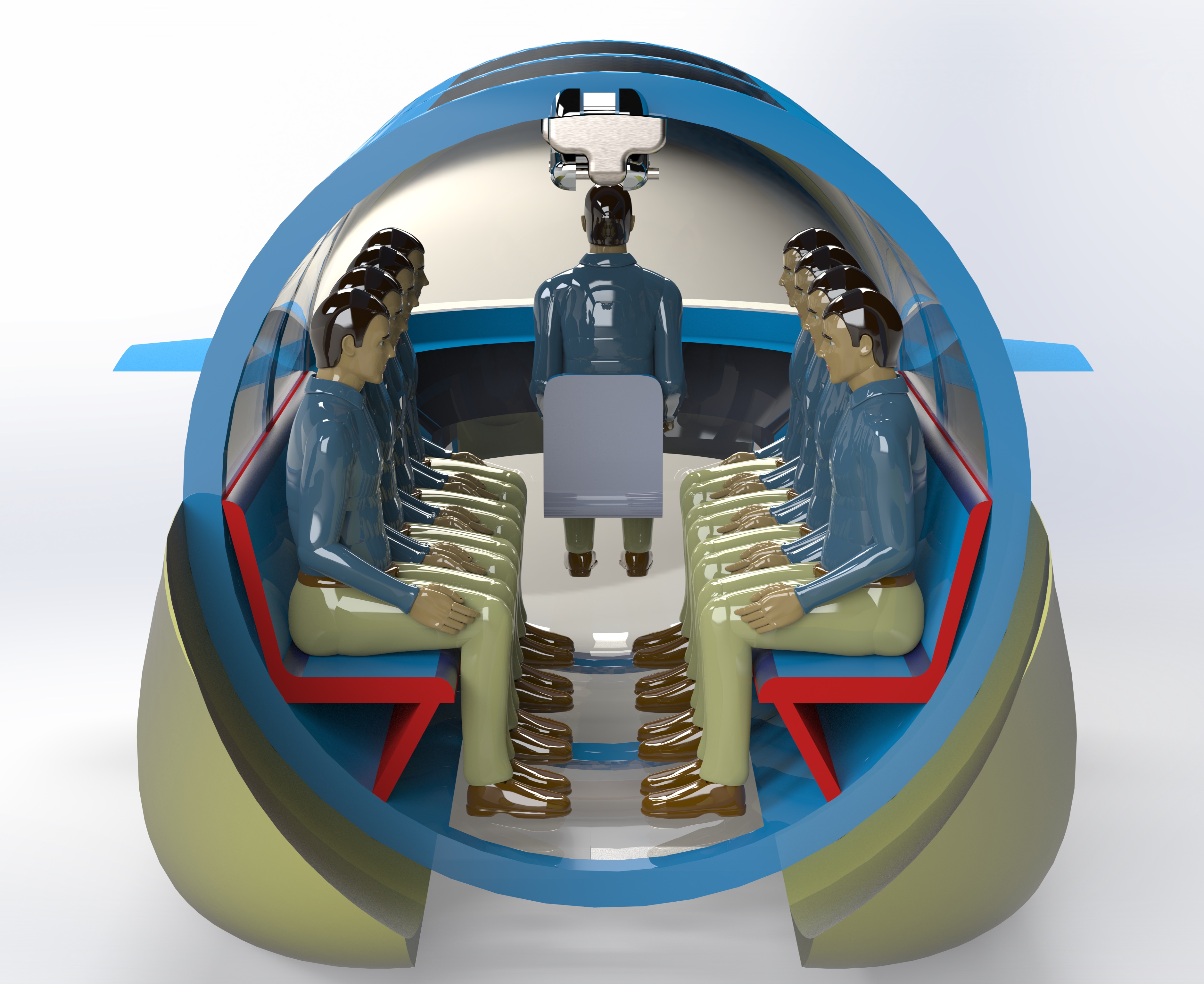

Passenger Vision

Transparent polymethyl methacrylate, commonly known as acrylic plastic or by the brand name Plexiglass is by far the most common transparent boundary material used in submarines and submersibles. The acrylic windows were machined as truncated cones and the material was used because unlike glass or fused quartz it deforms elastically under pressure without fracturing and as the pressure on the exterior face of the window increases the seal at the window-pressure hull interface becomes more secure.

Acrylic is a remarkable material well suited for subsea applications. It is abrasive resistant with excellent weatherability and it is optically highly transparent. The materials strength to weight ratio is equivalent to that of low carbon steel and its plasticity allows it to tolerate large stress concentrations in compression. In addition, the materials refractive index closely approximates that of seawater so that the outside surface of an acrylic window underwater effectively disappears, providing an immersive experience for the viewer. In submarine applications acrylic windows typically have a life of 10,000 dives.

Apam-Napat Submersible

Underwater Manned Mini-Sub

Humans have always been fascinated by the underwater world and inspired to find new ways to explore it. Submarines are limited for public use due to military classification issues and being expensive. This page introduces a new squat submarine. This squat submarine has 9-person capacity as a manned midget submersible using specific geometries of length-over-depth ratios (L/D) below four (Sarraf et al. 2022). The cause of such selection is to provide better visibility for the passengers to research and explore the sea. However, the geometrical features considerably change the hydrodynamic performance of the submarine, for example, by causing pressure drag. This submarine hull is equipped with a hemisphere bow with a cylindrical middle body to provide more vision for the passengers for research and tourist purposes.

Apam-Napat Submersible

Underwater Manned Mini-Sub

Humans have always been fascinated by the underwater world and inspired to find new ways to explore it. Submarines are limited for public use due to military classification issues and being expensive. This page introduces a new squat submarine. This squat submarine has 9-person capacity as a manned midget submersible using specific geometries of length-over-depth ratios (L/D) below four (Sarraf et al. 2022). The cause of such selection is to provide better visibility for the passengers to research and explore the sea. However, the geometrical features considerably change the hydrodynamic performance of the submarine, for example, by causing pressure drag. This submarine hull is equipped with a hemisphere bow with a cylindrical middle body to provide more vision for the passengers for research and tourist purposes.

Optimal Operation, High Standard, Great Safety

ICE presents a new midget submarine (mini-submarine) with the ability for independent movement, lightweight, and up to 9-person capacity. This type of submarine has attracted considerable focus over recent years, and some commercial factories are also working in this field. The naval submarine design science aims to find the best-suited shape for the vessel to provide better hydrodynamic functionality and extend the range and time of the operation by decreasing the energy demand needed for the movement of the vessel. In fact, submarines encounter limited energy on the surface and submerged navigation; therefore, the minimum resistance is vital in the submarine hydrodynamic design. A body shape with a suitable hydrodynamic condition can reduce drag effects on the hull to minimize the operational energy demand. Consequently, the Apam-Napat submersible is design in order to operate in a complete optimized way. The design went through a number of iterations before it reached its current optimum state.

It took considerable time and effort to reach the current design status that we believe to be absolutely optimum. An emplacement depth range of from 20 meters provides significant versatility of site location and the modular nature of the design means later expansion or the development of larger or smaller submarine is simple.

In this submarine, there has never been a serious injury or fatality to any passenger aboard an ABS classed submarine or submersible. Our intention is to build the Apam-Napat submersible to the rigorous safety standards we apply to submarine projects and to have the standards and implementation verified by outside engineering experts that report to the insurance underwriters. The design specifications generally follow the requirements of such regulations as proposed in Rules for Building and Classing Underwater Systems and Vehicles by the Iranian Society of Safety Standard for Pressure Vessels for Human Occupancy. In fact, we are taking the principals, materials, techniques and structures from what has been demonstrated to be the worlds safest form of transportation and utilizing them to build a submarine structure that is considerably safer.

The submarine has been designed specifically to have a net positive impact on the environment. Apam-Napat submersible most important environmental effect will be to introduce thousands of people to the sub-sea world and to promote environmental stewardship, for you can only expect people to act to protect the marine environment if they understand the issues and can see what they are protecting first-hand. We are committed to environmental sensitivity and stewardship..

Optimal Operation, High Standard, Great Safety

ICE presents a new midget submarine (mini-submarine) with the ability for independent movement, lightweight, and up to 9-person capacity. This type of submarine has attracted considerable focus over recent years, and some commercial factories are also working in this field. The naval submarine design science aims to find the best-suited shape for the vessel to provide better hydrodynamic functionality and extend the range and time of the operation by decreasing the energy demand needed for the movement of the vessel. In fact, submarines encounter limited energy on the surface and submerged navigation; therefore, the minimum resistance is vital in the submarine hydrodynamic design. A body shape with a suitable hydrodynamic condition can reduce drag effects on the hull to minimize the operational energy demand. Consequently, the Apam-Napat submersible is design in order to operate in a complete optimized way. The design went through a number of iterations before it reached its current optimum state.

It took considerable time and effort to reach the current design status that we believe to be absolutely optimum. An emplacement depth range of from 20 meters provides significant versatility of site location and the modular nature of the design means later expansion or the development of larger or smaller submarine is simple.

In this submarine, there has never been a serious injury or fatality to any passenger aboard an ABS classed submarine or submersible. Our intention is to build the Apam-Napat submersible to the rigorous safety standards we apply to submarine projects and to have the standards and implementation verified by outside engineering experts that report to the insurance underwriters. The design specifications generally follow the requirements of such regulations as proposed in Rules for Building and Classing Underwater Systems and Vehicles by the Iranian Society of Safety Standard for Pressure Vessels for Human Occupancy. In fact, we are taking the principals, materials, techniques and structures from what has been demonstrated to be the worlds safest form of transportation and utilizing them to build a submarine structure that is considerably safer.

The submarine has been designed specifically to have a net positive impact on the environment. Apam-Napat submersible most important environmental effect will be to introduce thousands of people to the sub-sea world and to promote environmental stewardship, for you can only expect people to act to protect the marine environment if they understand the issues and can see what they are protecting first-hand. We are committed to environmental sensitivity and stewardship..

Operational mechanism

The submarine is towed by a ship between the port and desired locations. It is then launched from the ship to operate independently at the intended location. Alternatively, the submarine can stay connected to the ship and be towed throughout the operation. The towing function provides simple operational mechanisms, low-cost operation and maintenance, and higher operational time. The towing function provides a simpler, less noisy, and lower-cost operation at site, while allowing higher operational time.

This arrangement can be used for exploration, research, maintenance, and tourist attractions. Originally, the idea of towing a manned underwater vehicle was patented by Green (1962). The vehicle consisted of an open hull with a tapered rear end design to carry a diver inside. In the present study, a squat submarine is used, which is of Apam-Napat SMSD type introduced by Sarraf et al. (2022). This submarine is a manned midget submersible with a 9-person capacity using specific length-over-depth (L/D) ratios below four, contrary to conventional submarines which use higher L/D ratios (Moonesun and Korol 2017, Arentzen and Mandel 1960, Sarraf et al. 2022). The cause of such selection is to provide better visibility for the passengers to research and explore the sea. This geometric feature is in contrast to conventional submarines that are designed to be efficient at high velocities and to remain undetected. In addition, this towed submarine eliminates the need for a propulsion system and fuel carrying. L/D ratios below four considerably change the hydrodynamic performance of the vessels.

Operational mechanism

The submarine is towed by a ship between the port and desired locations. It is then launched from the ship to operate independently at the intended location. Alternatively, the submarine can stay connected to the ship and be towed throughout the operation. The towing function provides simple operational mechanisms, low-cost operation and maintenance, and higher operational time. The towing function provides a simpler, less noisy, and lower-cost operation at site, while allowing higher operational time.

This arrangement can be used for exploration, research, maintenance, and tourist attractions. Originally, the idea of towing a manned underwater vehicle was patented by Green (1962). The vehicle consisted of an open hull with a tapered rear end design to carry a diver inside. In the present study, a squat submarine is used, which is of Apam-Napat SMSD type introduced by Sarraf et al. (2022). This submarine is a manned midget submersible with a 9-person capacity using specific length-over-depth (L/D) ratios below four, contrary to conventional submarines which use higher L/D ratios (Moonesun and Korol 2017, Arentzen and Mandel 1960, Sarraf et al. 2022). The cause of such selection is to provide better visibility for the passengers to research and explore the sea. This geometric feature is in contrast to conventional submarines that are designed to be efficient at high velocities and to remain undetected. In addition, this towed submarine eliminates the need for a propulsion system and fuel carrying. L/D ratios below four considerably change the hydrodynamic performance of the vessels.

Passenger Vision

Transparent polymethyl methacrylate, commonly known as acrylic plastic or by the brand name Plexiglass is by far the most common transparent boundary material used in submarines and submersibles. The acrylic windows were machined as truncated cones and the material was used because unlike glass or fused quartz it deforms elastically under pressure without fracturing and as the pressure on the exterior face of the window increases the seal at the window-pressure hull interface becomes more secure.

Acrylic is a remarkable material well suited for subsea applications. It is abrasive resistant with excellent weatherability and it is optically highly transparent. The materials strength to weight ratio is equivalent to that of low carbon steel and its plasticity allows it to tolerate large stress concentrations in compression. In addition, the materials refractive index closely approximates that of seawater so that the outside surface of an acrylic window underwater effectively disappears, providing an immersive experience for the viewer. In submarine applications acrylic windows typically have a life of 10,000 dives.

Passenger Vision

Transparent polymethyl methacrylate, commonly known as acrylic plastic or by the brand name Plexiglass is by far the most common transparent boundary material used in submarines and submersibles. The acrylic windows were machined as truncated cones and the material was used because unlike glass or fused quartz it deforms elastically under pressure without fracturing and as the pressure on the exterior face of the window increases the seal at the window-pressure hull interface becomes more secure.

Acrylic is a remarkable material well suited for subsea applications. It is abrasive resistant with excellent weatherability and it is optically highly transparent. The materials strength to weight ratio is equivalent to that of low carbon steel and its plasticity allows it to tolerate large stress concentrations in compression. In addition, the materials refractive index closely approximates that of seawater so that the outside surface of an acrylic window underwater effectively disappears, providing an immersive experience for the viewer. In submarine applications acrylic windows typically have a life of 10,000 dives.